What is well control equipment

Overview

During drilling operations, in order to prevent formation fluid from invading the well, the drilling fluid column pressure in the well should always be kept slightly greater than the formation pressure. However, in actual drilling operations, the drilling fluid column pressure in the well is often lower than the formation pressure due to the influence of various factors, causing the pressure balance in the well to be destroyed, resulting in a blowout, resulting in personal casualties, damage to the drilling rig, and damage to the oil layer.

Drilling construction operations require certain technologies and equipment, and implementation of monitoring and control to prevent blowouts. Once a blowout occurs, the parallel port can be controlled promptly and accurately, the well killing operation can be carried out, and the pressure control of the oil and gas well can be restored. Sometimes wellhead facilities are seriously damaged and oil and gas wells lose pressure control, requiring rescue operations. The equipment used to complete the above work is generally called well control equipment. Well control equipment is a general term for a set of special equipment, instruments and tools used to implement oil and gas well pressure control technology.

Therefore, understanding the performance of well control equipment, installing and maintaining it correctly so that the well control equipment can perform its proper function is an important guarantee for good oil and gas well pressure control.

Well control equipment should have the following functions

1. Prevent blowout. During drilling operations, the hydrostatic column pressure of the drilling fluid in the wellbore should always be slightly greater than the formation pressure to prevent the formation of blowout conditions.

2. Detect overflow in time. Monitor oil and gas wells to detect blowout signs as early as possible and take control measures as early as possible.

3. Quickly control the blowout. After overflow, kick, and blowout occur, shut down the well quickly and implement well killing operations; re-establish pressure balance control in the well.

4. Handle complex situations. In the event that an oil and gas well loses control, perform fire-fighting and rescue operations.

Well control equipment consists of the following: equipment, instruments and tools.

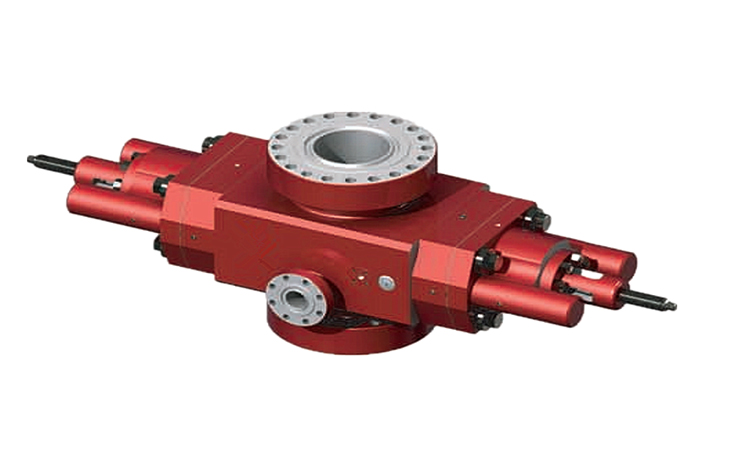

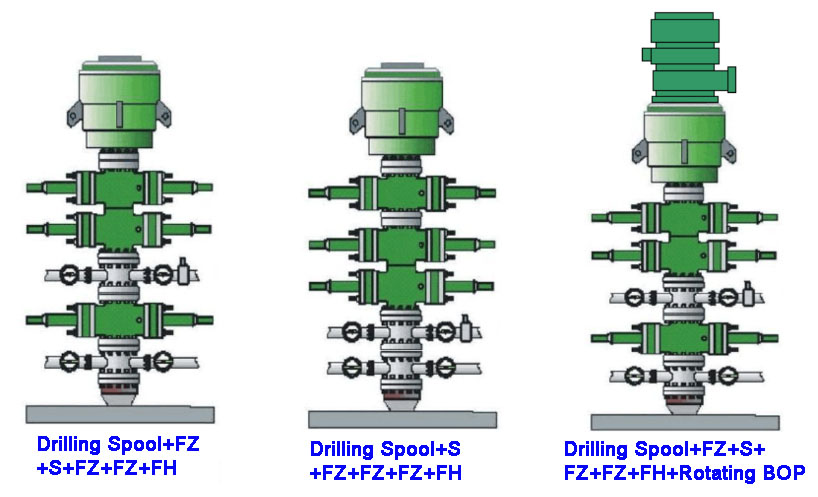

1. Wellhead BOP group: annular BOP, ram BOP, drilling spools, etc.

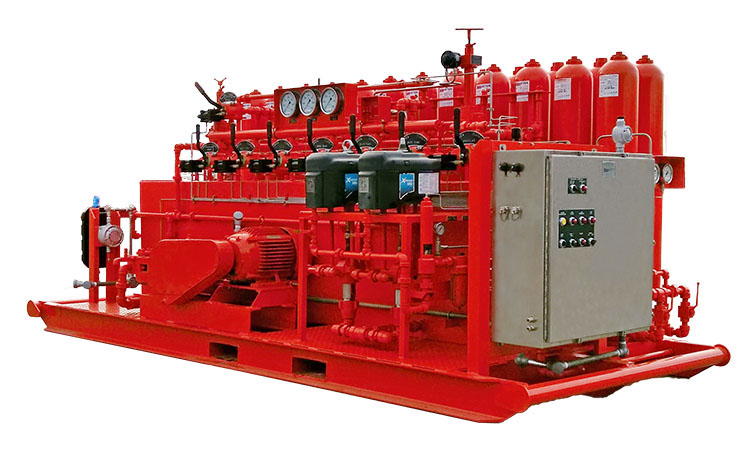

2. Control system: Accumulator Unit, remote control device, auxiliary remote control device;

4. Blowout prevention tools in drilling tools: kelly ball valve, drill pipe back pressure valve, input check valve, etc;

5. Weighted drilling fluid device: barite powder mixing funnel device; barite powder pneumatic unloading device;

6. Drilling fluid injection device;

7. Drilling fluidgas separator;

8. Monitoring instruments: drilling fluid tank level monitor, methane, hydrogen sulfide and other detectors;

9. Special operation equipment: snubbed tripping and pressurizing device, obstacle clearance, fire extinguishing equipment, etc.

Basic flow of well control operations

During normal drilling operations, the drilling pump inhales the drilling fluid from the drilling fluid storage tank and circulates it to the bottom of the well through the surface high-pressure manifold, riser, hose, faucet, kelly, drill pipe, drill collar, and drill bit. The cuttings are carried back up the annulus, and after arriving at the wellhead, the drilling fluid is exported through the anti-overflow pipe to the vibrating screen, degasser, and desander. The purified drilling fluid returns to the drilling fluid tank.

After an overflow occurs, close the blowout preventer and shut down the well. When killing the well, the drilling fluid pump will suck the drilling fluid from the drilling fluid tank through the surface high-pressure manifold, riser, hose, faucet, kelly, and drill pipe. , drill collar, and drill bit to the bottom of the well, and remove the intruding fluid from the well, through the four-way side hole to the choke manifold, and regulate the annular pressure through the choke valve. The returned drilling fluid is led to the drilling fluid gas separator through the return line. After the invading gas is removed, the qualified drilling fluid is led to the drilling fluid tank. The cleared gas is led to a safe place for combustion through the exhaust line to prevent pollution.

Hydraulic blowout preventer features:

1. Move quickly

Hydraulic sealing time of annular blowout preventer.

Generally no more than 30 seconds.

The hydraulic sealing time of the ram blowout preventer is 3-8 seconds.

The time to open the hydraulic discharge valve is 3 seconds.

2. Easy to operate, safe and reliable: the opening and closing of the wellhead blowout preventer are hydraulically operated (it is a hydraulic blowout preventer), and are controlled by pneumatic or hydraulic pressure.

3. Convenient on-site maintenance: If the ram of the ram blowout preventer is broken and the rubber core of the annular blowout preventer is broken, they can be replaced on site.

Blowout preventer combination selection

When combining wellhead blowout preventers, the main factors to consider are:

1. Diameter size

The nominal diameter should match the casing size under the casing head.

2. The pressure level of the pressure resistance capability should be greater than the expected maximum wellhead pressure that may occur.

3. Type and quantity

Quickly shut down the well under various conditions such as an empty well, a drilling tool in the well, and a different outer diameter of the drilling tool.

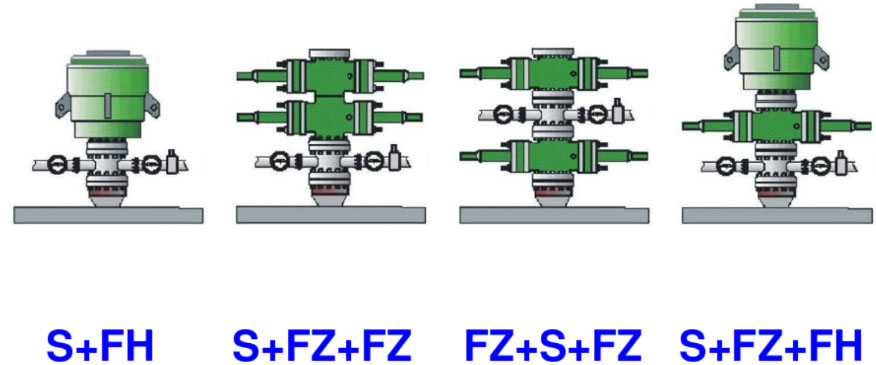

14MPa wellhead blowout preventer combination form

21MPa/35MPa wellhead blowout preventer combination form

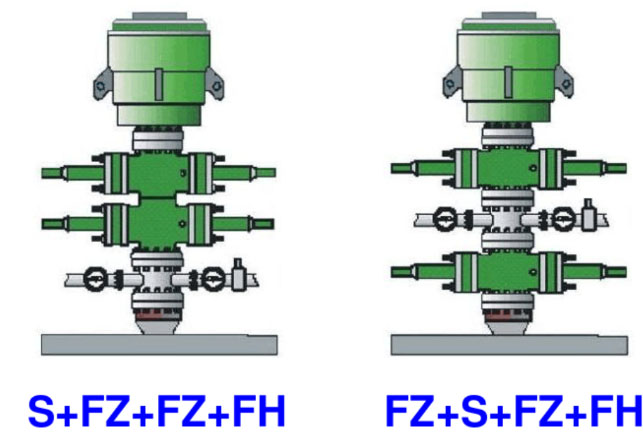

70MPa/105MPa wellhead blowout preventer combination form

Sino Mechanical Equipment provides various oil drilling equipment, such as: Annular BOP, Single Ram BOP and Double Ram BOP,BOP Stacks, Accumulator Unit, BOP Control System, Drilling Spools,Integral Fittings,Choke and Kill Lines, Hose Loops, etc. It is committed to developing and providing high-quality oil drilling equipment to meet the changing needs of customers and contribute more to the development of the petroleum industry.