Buy high quality Workover rigs from Sino Mechanical. We have in stock Workover Rigs for sale for both onshore as well as offshore Workover purposes at affordable prices. Contact us to get the latest price.

The latest truck mounted electric workover rigs developed by Sino Mechanical is energy-saving and environmentally friendly, which is with low noise and low operating cost. Our workover rigs cover various well workover operations in the oil and gas industry.

Sino Mechanical manufactures high-quality rotary drilling rigs with competitive prices. Piling Rig mainly used in large quarries, open pit mines, oil extraction and other fields.

Sino Mechanical has more than 20 years extensive experience in the field of water well drilling rigs. We design and manufacture safe, reliable and efficient water well drilling rigs and equipment to meet all your drilling needs.

Sino Mechanical land drilling rigs are focused on optimizing your drilling operations. We offer all our conventional land rigs with a full package for fast movement and transportation.

Drilling mud pumps are dedicated to drilling operations. Sino Mechanical manufactures and supplies high-performance, robust, and reliable Triplex Mud Pumps for land and offshore drilling applications.

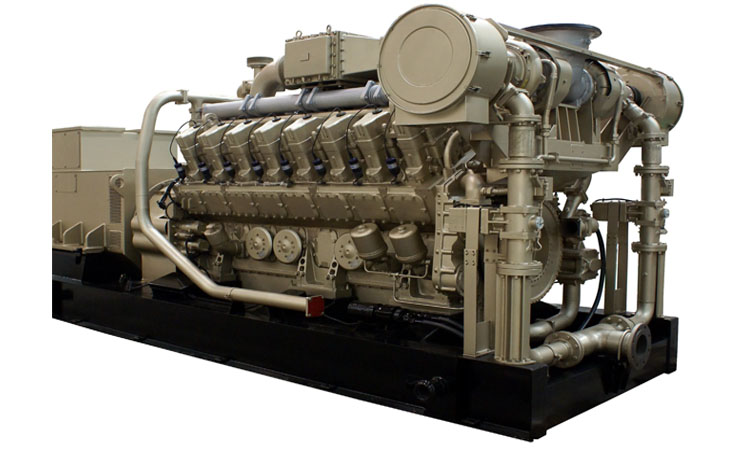

Sino Mechanical manufactures and supplies high-performance and reliable Oilfield Diesel Engines for drilling rigs applications work exceptionally hard.

Sino Mechanical's commercial and industrial generator sets come in a range of options to match your power needs, making selecting and installing simple.

Sino Mechanical offers weight indicator systems. The Weight Indicator system consists of a Gauge and a Deadline Diaphragm, connected by a high-pressure Hose to accurately define tension, weight, or compression.

The Sino Mechanical of Power Tongs are used on drilling rigs to screw and unscrew tubing or casing to a specific torque. We stock hard to find tubing and casing power tongs.

Sino Mechanical manufactures and supplies high-performance, robust, and reliable deadline anchors for drilling rig.

Sino Mechanical have casing Elevator / Spiders to handle casings up to 24-1/2”. Slip Type Elevator / Spider are mechanized tools with air operating. They are easy to operate and dependable enough.

What is the Drilling and Workover equipment?

Drilling equipment includes workover rigs, geothermal drilling rigs (rotary drilling rigs), water well drilling rigs, oil well drilling rigs (land drilling rigs) and drilling rig components.

Sino Mechanical is supplier and manufacturer of drilling and workover equipment. We provide various types of Drilling Rigs and Drilling Rig Components, including Generator Sets, Drilling Mud Pumps, Diesel Engines, Diesel Engine Generator Radiators, Power Tongs, Elevators and Spiders, Wire Rope, Weight Indicators, Deadline Anchors, Traveling Block and Hook Blocks and Drawworks.

Workover rigs

A workover rig can be called completion wells or pulling units. It is s a specially designed rig that makes it easier to take out or insert tubing into a well. The purpose of a workover rig is to replace a well with a new completion. Workover rig means a mobile self-propelled rig used to perform one or more remedial operations, such as deepening, plugging back, pulling and resetting liners, on a producing oil or gas well to try to restore or increase the well’s production. Sino Mechanical truck/trailer mounted workover rig is mechanically and hydraulically driven. Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. Sino Mechanical workover rig series cover the workover depth from 2500m to 7000m and drawworks power from 250HP to 1000HP. Our workover rig is featuring high operation load, reliable performance, excellent off-road performance, convenient movement and low operation cost.

Rotary Drilling Rigs

Rotary drilling rig also known as rotary rig, pile drilling machine, bored pile machine and pile drilling machinery. A rotary drilling rig is a comprehensive drilling rig. A rotary drilling rig is the equipment used for drilling in most wells, which includes an engine and a hoisting, rotating and mud circulating system. The operating equipment of a rotary drilling rig can be divided into three systems: hoisting, rotating, and circulation.

When you buy a Sino Mechanical rotary drilling rig with competitive price, you know exactly what you’re getting: a reliable, accurate, powerful machine that will help your operation run smoothly and productively.

Water Well Drilling Rigs

Water well drilling, whick is also called water well drilling equipment, is the process of drilling holes in the earth's surface for the purpose of reaching a groundwater source. Water well drilling rigs are divided into small water well drilling rigs and crawler water well drilling rigs.

Oil well drilling rigs are machines designed to drill several thousand feet into the earth’s crust. Water well drilling rigs are similar machines, but only drill several hundred feet into the earth.

Sino Mechanical’s water well drilling rigs are designed for safety, reliability, and productivity. Sino Mechanical has a complete line of hydraulic top-head drive drilling rigs, designed for water well drilling and other applications requiring air or mud rotary as well as down-the-hole hammer drilling methods.

Land Drilling Rigs

A land drilling rig is a rig used to drill holes onshore to allow the extraction of oil or natural gas, and there are two different types of land drilling rigs. And there are conventional and mobile drilling rigs. Onshore drilling rig is drilling downhole to explore crude oil in Petroleum industrial business. Sino Mechanical’s drilling rig portfolio is focused on optimizing your drilling operations. Sino Mechanical offers all our conventional land drilling rigs with full packages that consists of top drives, drawworks, BOP stack, pipe handling systems, BOP control systems, iron roughnecks, rotary tables, power control units, solid control systems, low-pressure mud systems, catwalks and skidding systems.

What are the main drilling rig components?

A drilling rig is the equipment used to drill a wellbore. Drilling rigs can be massive structures housing equipment used to drill water wells, oil wells, or natural gas extraction wells, or they can be small enough to be moved manually by one person and such are called augers. They can be used onshore and offshore. Drill rigs are used to explore the geological conditions of an area to find the location of the desired product and the optimum points for extraction. The drilling rig is fully equipped with components such as generator sets, drilling mud pumps, diesel engine generator radiators, power tongs, elevators and spiders, wire rope, weight indicators, deadline anchors, drawworks, traveling block and hook blocks, diesel engines and auxiliary equipment.

Sino Mechanical has different types of rigs, such as Workover rigs, Rotary Drilling Rigs, Water Well Drilling Rigs and Land Drilling Rigs. It is important to keep in mind the exact type of drilling rigs that are being discussed as well as the location that they are used in. Both of these factors have a dramatic impact on the type of rig that is used and the reasons that it is there in the first place.

Drilling and Workover Equipment Supplier

Sino Mechanical has more than 20 years experiences in the field of drilling equipment. We are global drilling equipment supplier and offer a wide range of drilling equipment. Sino Mechanical is an exclusive supplier of leading Oil and Gas equipment manufacturers. We design, manufacture, and sell drilling equipment, workover equipment drilling rig componenets, and complete drilling packages for your drilling applications.

What is a workover rig and why it is important?

According to Wikipedia, “The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically though, it will refer to the expensive process of pulling and replacing a completion.”

We manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs. The Rig packages can be shipped worldwide. The main workover rig parts consist of Rig for Drilling, Drilling equipment, Top drives, Triplex mud pumps, Blow out preventers, BOP control systems, Well control equipment, Solids control equipment and Oil country tubular goods. Workover types of Rig are available in the form of the single drum and the double drum.

Workover rigs contain a full line of drilling packages as well. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

Workover rigs are very similar to drill rigs in that they are truck-mounted mobile rigs that travel between job sites on public roads.

What are rotary drilling rigs?

It can use various underlying layers. It has the characteristics of fast pore forming, less pollution and strong fluidity. The short auger bit can be used for dry excavation, and the rotary bit can also be used for wet excavation in mud wall conditions. The rotary excavator can drill into the hard ground with the punch, and then dig the hole. Cooperate with the reaming head drill to ream the hole at the bottom of the hole. The rotary excavator adopts multi-layer telescopic drill pipe, which has the advantages of less auxiliary drilling time, low labor intensity, no mud circulation, slag discharge, cost saving, etc., and is especially suitable for the foundation construction of urban construction.

Rotary drilling rig is suitable for building into a hole in the foundation engineering construction machinery operations. Mainly for sand, clay, silty soil and other soil construction in the building, railway, bridge piles, diaphragm wall, foundation reinforcement and other foundation construction has been widely used.

The Rotary Drilling Rigs are track or lorry mounted with a diamond tipped core bit and use an air, air/mist, clean water, foam or polymer flushing medium to assist with the drilling. There are two types of Rotary drilling methods, Rotary Core Drilling and Rotary Open Hole Drilling. The main part of the rotary system are as follows: Swivel, Rotary hose, Kelly, Rotary drive (master pushing, kelly pushing), Rotary table and Drilling string.

Sino Mechanical’s rotary drilling rig covers every need and every application, no matter how big or small, no matter how harsh or remote. We offer drills in every size class — small, medium, large and ultra. You can count on the same level of quality, reliability and support that comes standard with every Sino Mechanical drill. All of our drills use common parts, components and technologies.

Rotary drilling uses a sharp, rotating drill bit to dig down through the Earth’s crust. Much like a common hand-held drill, the spinning of the drill bit allows for penetration of even the hardest rock. Rotary drilling rig is a kind of piling machinery suitable for hole-forming operations in building foundation engineering. The rotary drilling rig has the characteristics of large installed power, large output torque, large axial pressure, flexible maneuverability, and high construction efficiency. Rotary drilling rigs are generally powered by diesel engines, fully hydraulically driven, crawler walking, 360-degree rotation, and self-propelled landing gear. With the characteristics of speed adjustment, electronic automatic monitoring, etc., it overcomes the shortcomings of the previous electric drilling machine and will gradually replace the electric drilling machine. The rotary drilling rig breaks the rock and soil through the rotation of the barrel drill bit with a valve at the bottom, and directly loads it into the drill bit, and then lifts the drill bit out of the hole to unload the soil by the lifting device of the drilling rig and the telescopic drill rod. The soil is continuously taken and unloaded until the drill reaches the designed depth. For rock and soil layers with good cohesion, dry or clear water drilling technology can be used. And in loose, easily collapsible stratum, then must adopt static mud retaining wall drilling technology. Rotary drilling rigs are widely used in foundation bored pile projects such as railways, highway bridges, municipal construction, and high-rise buildings.