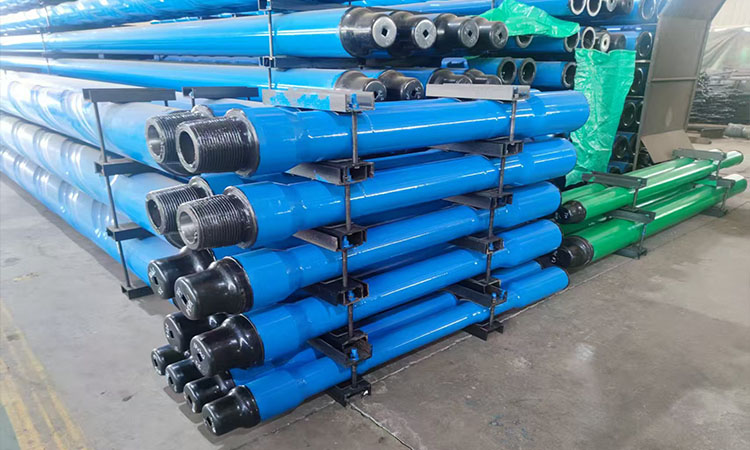

Drill pipe pup joints of Sino Mechanical Equipment are ready to be shipped to European client

Drill pipe pup joints of Sino Mechanical Equipment have completed production and inspection, and are ready for shipment.

Drill pipe pup joints are important components for connecting drill pipes in oil and gas drilling operations, ensuring the integrity of the drill string and power transmission.

1. Basic functions of drill pipe pup joints

Connecting drill pipes: connecting single drill pipes into a drill string to extend the well depth.

Transmitting power: bearing the torque and axial force of the drilling rig and driving the drill bit to rotate.

Seal drilling fluid: prevent leakage of high-pressure drilling fluid and maintain the pressure of the circulation system.

Anti-wear protection: protect the threads of the drill pipe body and reduce wear.

2. Main types of drill pipe pup joints

(1) Classification by structure

Internal flush type (IF, Internal Flush)

The inner diameter is consistent with the drill pipe body, with low flow resistance, suitable for high-pressure drilling fluid circulation.

Full hole type (FH, Full Hole)

The inner diameter is slightly smaller than the drill pipe body, balancing strength and fluidity.

Regular (REG, Regular)

The outer diameter of the joint is thickened, the strength is high, but the inner diameter is the smallest, and it is often used for high-intensity operations.

(2) Classification by thread type

API standard threads (such as NC, FH, REG, etc.): strong versatility, in line with American Petroleum Institute standards.

Special threads (such as VAM, TM, etc.): high-performance design, better sealing, and strong fatigue resistance.

(3) Rotary Shouldered Connection

The precision-machined shoulder surface (Shoulder) and thread withstand high torque, commonly used in deep wells and ultra-deep wells.

3. Key parameters of drill pipe pup joint

Outer diameter and inner diameter: need to match the drill pipe size (such as 2-7/8″, 3-1/2″, etc.).

Thread specifications (such as NC26, NC38): determine the connection strength and compatibility.

Torque capacity: affects the torsional strength, and needs to be selected according to the well depth and drilling rig power.

Material grade: usually high-strength alloy steel (such as AISI 4145H), quenched and tempered.

4. Common problems and maintenance of drill pipe pup joint

Thread wear/damage: Check regularly to avoid failure due to fatigue or wrong threading.

Stress corrosion cracking: Anti-sulfur materials should be selected in environments containing hydrogen sulfide (H₂S).

Seal failure: Special threaded joints require special sealing grease (such as thread grease).

Makeup torque control: Overtightening or over-loosening will affect the life of the joint, and standard operation is required.

5. Drill pipe pup joint industry standards

API Spec 7-1: Standard thread size, tolerance and test requirements.

ISO 10424: Drill pipe joint standard of the International Organization for Standardization.

6. Drill pipe pup joint application scenarios

Conventional drilling: API standard joints can meet the needs.

Deep well/ultra-deep well: High-performance special threaded joints (such as double shoulder design) are required.

Horizontal well/extended displacement well: emphasizes bending fatigue resistance and sealing.

7. Features of drill pipe pup joint of Sino Mechanical Equipment

1) High strength and durability

High quality materials: alloy steel (such as AISI 4145H) is usually used and heat-treated, with high tensile, torsional and compressive strength, and can adapt to complex downhole loads.

Wear resistance: surface hardening treatment (such as chrome plating, carburizing) can reduce wear and extend service life, especially in abrasive formations.

2) Excellent sealing performance

Metal-to-metal sealing: advanced thread design (such as API standard thread or special buckle type) ensures sealing under high pressure and prevents drilling fluid leakage.

Auxiliary sealing technology: some joints use elastic sealing rings or coatings to further enhance the sealing effect.

3) Optimized thread design

Quick buckle: special threads (such as double shoulder joints) increase connection speed and reduce operation time.

Anti-fatigue performance: thread stress is evenly distributed, reducing stress concentration and reducing the risk of fatigue fracture.

4) Versatility and compatibility

Standardized interface: complies with API standards (such as NC, FH, etc.), can be matched with drilling tools from different manufacturers, and is easy to replace and repair.

Adapt to various working conditions: various designs (such as through-hole type, internal flat type) to meet different well depths, drilling pressure and torque requirements.

5) Improve drilling efficiency

Reduce failure risk: high reliability reduces downhole accidents (such as tripping, puncture leakage), and avoids non-productive time (NPT).

Efficient transmission power: ensure that drilling pressure and torque are effectively transmitted to the drill bit, and increase the mechanical penetration rate (ROP).

6) Economical

Long life design: reduce frequent replacement and reduce maintenance costs.

Modular replacement: only the joint needs to be replaced instead of the entire drill pipe when damaged, saving costs.

7) Adaptability to special environments

High temperature/high pressure wells: special materials or coatings are used to withstand extreme temperatures (such as deep wells or shale gas wells).

Corrosive environment: anti-corrosion treatment (such as nickel-based alloy plating) resists corrosive media such as H₂S and CO₂.

8) Improved safety

Anti-slip structure: Some designs include locking devices to prevent loosening underground and ensure safe operation.

Reduce vibration: Optimize threads to reduce vibration transmission and protect other drill components.

Drill pipe pup joint supplier

The core advantages of drill pipe joints are their high strength, sealing, efficient connection and adaptability, which directly improve the reliability, efficiency and economy of drilling operations. Different working conditions (such as deep wells and horizontal wells) require targeted selection of joint types (such as high-torque double shoulder joints) to maximize their performance.

Sino MechanicalEquipment is located in Shengli Oilfield, the second largest oilfield in China, and has long provided reliable and high-quality oil drilling tools and drilling equipment to drilling companies and oilfields.