Description

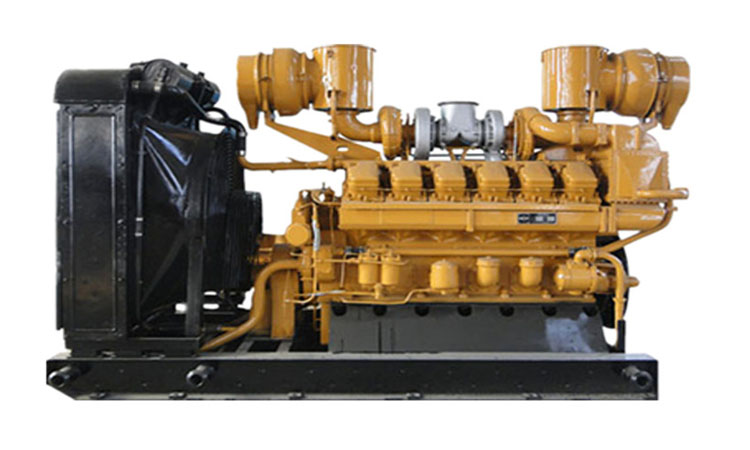

Overview of Diesel Engine

Diesel engine is a kind of power machinery, which uses diesel as fuel and converts the heat energy generated by the combustion of diesel into mechanical energy.

A diesel engine is an engine that burns diesel for energy release. It was invented by the German inventor Rudolf Diesel in 1892. To commemorate the inventor, diesel is represented by his surname Diesel, and the diesel engine is also called Diesel engine ( Diesel engine).

Cumbersome, loud noise, and black smoke make many people have a bad impression of diesel engines. After years of research and new technology applications, the status quo of modern diesel engines is no longer comparable to the past. Modern diesel engines generally adopt technologies such as electronically controlled injection, common rail, and turbocharged intercooling, and have made major breakthroughs in terms of weight, noise, and smoke, reaching the level of gasoline engines.

Diesel engines are widely used and are at the core of the industrial chain. Diesel engines are mainly used for final supporting products, such as high-power high-speed diesel engines are mainly used for heavy-duty vehicles, large buses, construction machinery, ships, generator sets, etc.

Features of Diesel Engine

1. The advantages of diesel engines are large output torque, high thermal efficiency, and good fuel economy.

2. The diesel engine is the same as the gasoline engine. Each working cycle also undergoes four strokes: intake, compression, power, and exhaust.

3. However, since the fuel used in the diesel engine is diesel, its viscosity is higher than that of gasoline, it is not easy to evaporate, and its ignition point is lower than that of gasoline. The mixture in the cylinder of the diesel engine is compression ignited, so the diesel engine does not need an ignition system.

4. When the diesel engine is working, air is sucked into the cylinder. When the air in the cylinder is compressed to the end, the temperature can reach 500-700°C and the pressure can reach 40-50 atmospheres. When the piston is close to the top dead center, the fuel injection nozzle of the fuel supply system injects fuel into the combustion chamber of the cylinder at a very high pressure in a very short time, and the diesel fuel forms fine oil particles, which are mixed with high-pressure and high-temperature air, and the combustible mixture burns by itself , The violent expansion produces explosive force, pushing the piston down to do work. At this time, the temperature can reach 1900-2000 ° C, and the pressure can reach 60-100 atmospheres. Therefore, the torque generated by the diesel engine is large.

5. Due to the high working pressure of the diesel engine, the relevant parts are required to have high structural strength and rigidity, so the volume of the diesel engine is relatively large; the manufacturing precision of the fuel injection pump and nozzle of the diesel engine is high.

6. In addition, the diesel engine works roughly and has high vibration and noise; diesel is not easy to evaporate, and it is more difficult to start cold at low temperature than gasoline engine. In addition, the power per liter index of a diesel engine is not as good as that of a gasoline engine (lower speed), and the emission of soot and particulates (PM) is more than that of a gasoline engine. Due to the above characteristics, early diesel engines are generally used in large and medium-sized trucks and related engineering vehicles and equipment.

7. With the development of diesel engine technology, a number of advanced technologies, such as direct injection, turbocharging, intercooling, electronic control, common rail and other technologies, have been applied to diesel engines, making the original shortcomings of diesel engines better. However, the advantages of diesel engines in terms of energy saving and CO2 emissions cannot be replaced by all heat engines including gasoline engines.

8. Nowadays, the application fields of diesel engines have become more and more extensive. They are used in many fields such as trucks, pickups, SUVs, excavators, forklifts, generators, garden machinery, agricultural machinery and diesel engine for drilling.

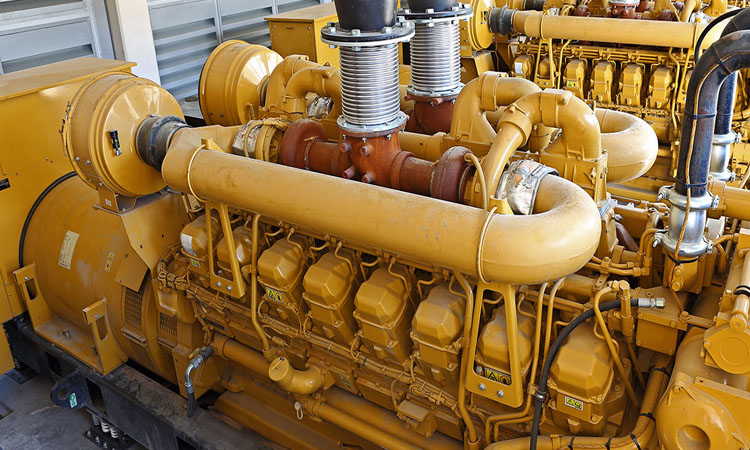

Diesel Engine Spare Parts

Diesel engine spare parts are the composition of the diesel engine. Diesel engine spare parts consists of the body cylinder liner, oil pan, cylinder head, piston connecting rod, flywheel crankshaft, transmission mechanism components, camshaft, starter, generator, intake pipe, exhaust pipe, air filter, oil pump, fan pulley components, oil filters, oil coolers, oil pipes, water pumps, water pipes, fuel pipes, fuel injectors, instruments, water tanks, superchargers, high-pressure oil pumps, etc.

Types of Diesel Engine

1. Electronically controlled in-line pump diesel engine

2. Pump nozzle diesel engine

3. Single pump diesel engine

4. Distribution pump diesel engine

5. Common rail diesel engine

Applications of Diesel Engine

1. Diesel engines for construction machinery

2. Diesel engines for agricultural machinery

3. Diesel engines for drilling operation

4. Vehicle supporting diesel engine

5. Diesel engine for forklift

6. Compressor supporting diesel engine

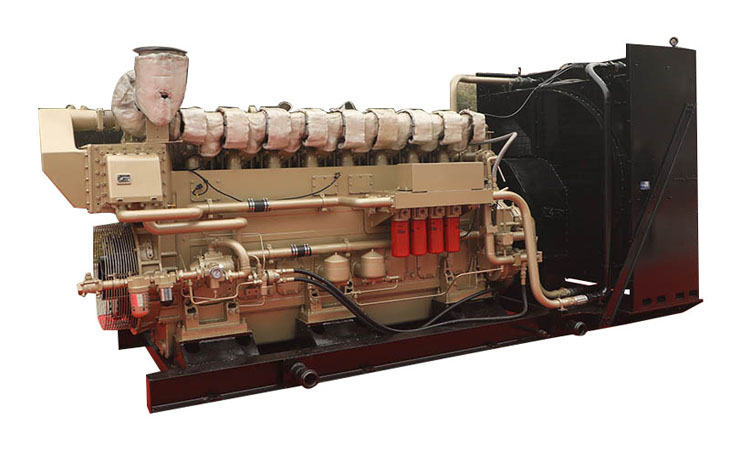

7. Diesel engine for power generation

8. Diesel engine for power generation

9. Generator sets, welding machines, and pumps are equipped with diesel engines.

10. Diesel engine for marine engine

Price of Diesel Engine

The Diesel Engine Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Diesel Engine for drilling and diesel engine spare parts. If you are looking for Diesel Engine or Diesel Engine spare parts, please kindly contact us to get the latest Diesel Engine price.

Diesel Engine Supplier

Sino Mechanical, as a Diesel Engine manufacturer and supplier, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Diesel Engine. We are global Diesel Engine supplier. We offer a wide range of drilling equipment and have Diesel Engine for sale. We also provide OEM services. We design, manufacture, and sell Diesel Engine for your drilling applications. If you want to know latest Diesel Engine price , don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Diesel Engine

|

Description |

Engine model |

Injection system |

Speed adjustment mode |

Cylinder&Arrangement |

Cylinders Bore,mm |

Piston Stroke,mm |

|

Engine with fan and radiator |

H12V190PZL |

Monoblock pump |

Electronic Speed Governor |

12 cylinders,V tyoe |

190 |

215 |

|

H12V190PZL-1 |

||||||

|

H12V190PZL-2 |

||||||

|

Description |

Genset model |

Rated power kw |

Rotation speed r/min |

Engine model |

Hydraulic transmission coupler/Torque Converter Model |

Height of center |

|

Hydraulic transmission coupling set |

CO2200/40 |

2200 |

1500 |

H16V190PZL |

YOTFJ875 |

760 |