What is blowout preventer(BOP)

Overview

During drilling operations, in order to prevent formation fluid from invading the well, the drilling fluid column pressure in the well should always be kept slightly greater than the formation pressure. However, in actual drilling operations, due to various influences, the drilling fluid column pressure in the well is often lower than the formation pressure, causing the pressure balance relationship in the well to be destroyed, resulting in a blowout. The result is personal casualties, damage to the drilling rig, damage to the oil layer, etc.

The so-called well control equipment is a general term for a set of special equipment, instruments and tools used to implement oil and gas well pressure control technology. Therefore, understanding the performance of well control equipment, installing and maintaining it correctly, and enabling the well control equipment to perform its proper functions are important guarantees for good oil and gas well pressure control. The most important equipment is the blowout preventer. There are two main types of common blowout preventers: universal blowout preventer and ram blowout preventer.

The annular blowout preventer is named after the annular shape of its sealing component, the rubber core. Also known as universal blowout preventer, multi-effect blowout preventer or spherical blowout preventer.

According to the shape of the rubber core, it can be divided into: conical annular BOP, spherical annular BOP, and cylindrical annular BOP.

Annular blowout preventer function

1) When there is a pipe string in the well, a rubber core can be used to seal the annular space formed by the pipe string and the wellhead;

2) The wellhead can be completely sealed when the well is empty;

3) During the process of drilling, milling, casing grinding, logging and salvage well falling objects, if overflow or blowout occurs, it can seal the space formed by the kelly, cables, wire ropes, tools for handling accidents and the wellhead. ;

4) With the cooperation of a pressure reducing and regulating valve or a small energy accumulator, the 18° butt welded pipe string joint without fine buckles can be forcibly lifted and lowered;

5) In case of severe overflow or blowout, it is used to cooperate with the ram blowout preventer and choke manifold to achieve soft shut-in.

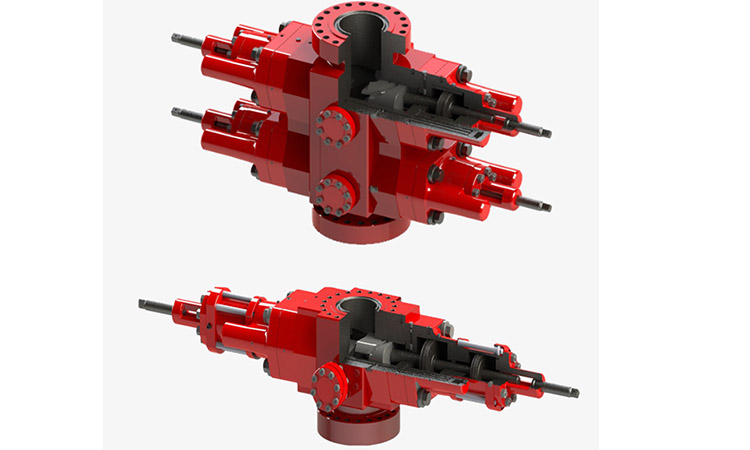

The ram blowout preventer uses hydraulic pressure to push the well sealing components - two rams with rubber cores - from the left and right sides to the center of the wellbore to seal the wellhead. Accordingly, it is called a ram blowout preventer.

According to the number of rams, they can be divided into: single-ram BOP, double-ram BOP, and three-ram BOP;

According to the function of the ram, it can be divided into: fully sealed ram BOP, semi-sealed ram BOP, shear ram BOP, variable diameter ram BOP;

According to the locking method, it can be divided into: manual locking ram BOP, hydraulic locking ram BOP;

According to the side door switching mode, it can be divided into: rotating side door gate blowout preventer and linear motion side door gate blowout preventer.

Ram blowout preventer function

1) When there is a drilling tool in the well, a semi-sealing gate corresponding to the size of the drilling tool can be used to close the wellhead annular space;

2) When there is no drilling tool in the well, the fully sealed gate can completely seal the wellhead;

3) When it is necessary to cut off the drilling tools in the well and completely seal the wellhead, the shear ram can be used to shear the drilling tools in the well to completely seal the wellhead;

4) The rams of some ram blowout preventers are load-bearing and can be used to hang drilling tools;

5) There are side holes on the casing of the ram blowout preventer, and the side holes can be used to throttle and relieve pressure;

6) Ram blowout preventer can be used to seal wells for a long time;

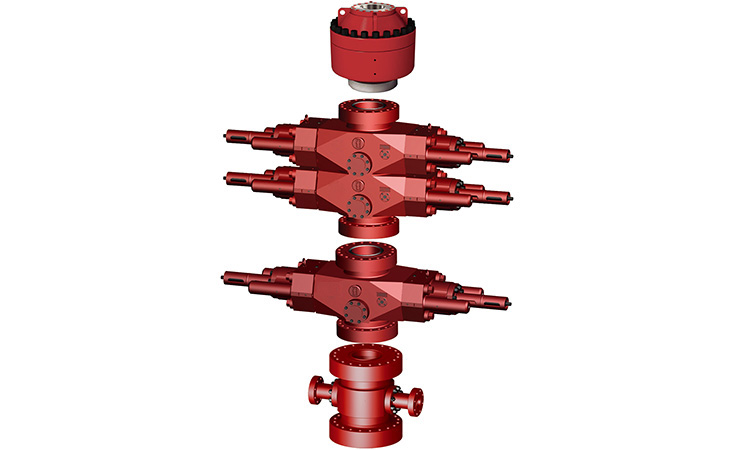

Blowout Preventer stacks(BOP stacks)

When applying blowout preventers on site, they can be used in multiple combinations as needed. Generally, the upper part is a universal blowout preventer, the middle part is a variable diameter ram blowout preventer, the bottom part is a shear ram blowout preventer, etc. There are many types according to the needs of the site. Different combinations. Various blowout preventer combinations are collectively referred to as blowout preventer packages (BOP).

Selection of blowout preventer combinations

Factors that should be considered when selecting a hydraulic blowout preventer combination include: well type, formation pressure, casing size, formation fluid type, personnel technical status, process technology requirements, climate impact, traffic conditions, material supply status, and environmental protection requirements, etc. . In short, it should be possible to achieve balanced drilling, ensure drilling safety and save drilling costs.

1) Selection of pressure level

The working pressure of the hydraulic blowout preventer combination depends on the internal pressure resistance strength of the casing used, the fracture pressure of the formation and the maximum wellhead pressure expected to be endured. But it is mainly determined based on the maximum wellhead pressure that the blowout preventer combination is expected to withstand. There are five types of blowout preventer pressure levels: 14MPa, 21 MPa, 35MPa, 70MPa, 105MPa, and 140MPa.

2) Selection of diameter

The diameter of the blowout preventer assembly depends on the casing size in the well structure design, that is, it must be slightly larger than the outer diameter of the connected casing. There are nine types of blowout preventer diameters: 180mm, 230mm, 280mm, 346mm, 426mm, 476mm, 528mm, 540mm, 680mm. Among them, 230mm, 280mm, 346mm and 540mm are commonly used on site.

3) Choice of combination form

The selection of combination form is mainly based on formation pressure, drilling process requirements, drilling tool structure and equipment matching conditions.

Supplier of BOP

Sino Mechanical Equipment provides various oil drilling equipment, such as:Annular BOP, Single Ram BOP and Double Ram BOP,BOP Stacks,Accumulator Unit, BOP Control System, Drilling Spools,Choke and Kill Lines,Hose Loops, drilling mud pumps and accessories,etc. It is committed to developing and providing high-quality oil drilling equipment to meet the changing needs of customers and contribute more to the development of the petroleum industry.