Common faults and solutions of mud pumps

General measures for judging and troubleshooting mud pump failures

1. Look: During the operation of the mud pump, pay attention to observe whether there are any abnormalities. The observation items include: whether the crosshead moves evenly; whether the connecting rod stops during movement; whether the steel sleeve moves; whether there are mud thorns. Leak: The pressure gauge pointer swings.

2. Listen: During the operation of the mud pump, pay attention to the sounds: whether there is metal knocking sound at the power end; whether there is metal knocking sound and mud knocking sound at the liquid end.

3. Touch: When the mud pump is running, pay attention to the temperature of the bearings and the pump itself.

4. Dismantle: When initially identifying the location of the mud pump failure, the disassembly method should be used to determine the origin of the failure.

Common faults and solutions of mud pumps

No. | faults | reason | solutions |

1 | Pump pressure drops | 1.Air entering the pipeline 2.A certain valve is not working | 1.Replace seals 2.Check valve working condition 3.Circulating exhaust |

2 | Reduced displacement | 1.The liquid level drops 2.The suction filter is blocked | 1.Raise liquid level 2.Clean the filter |

3 | There is abnormal noise in the pressure fluctuation pipeline | 1.The piston or valve body or valve seat is punctured 2.The guide body is stuck 3.There is foreign matter between the valve bodies | 1.Replace damaged parts 2.clean obstructions 3.circulate exhaust |

4 | Noise in cylinder liner | 1.Piston nut loosened 2.The cylinder liner gland is loosened 3.The clamp bolts are loose 4.The water supply is not good | 1.Fasten 2.Check the water seal

|

5 | water hose swing | 1.Air bag failure 2.discharge filter blocked

| 1.Replace air bag 2.cleaning blockage |

6 | Warning shows hole leaking mud | Seal failure | Replace the corresponding seals |

7 | Horizontal or vertical abnormal noise in the liquid cylinder | 1. Spring is broken 2. Valve rubber failure 3. Valve seat punctured 4. Guide body hole worn | Replace damaged parts |

8 | lubricant oil in the water tank | 1. The fender gasket is broken 2. The positioning pin of the fender has fallen. 3. The seal of the middle tie rod has failed. 4. The cross head is eccentrically worn. | 1. Replace the damaged parts 2. Correct the crosshead coaxiality) 3. Tighten the positioning pin |

9 | Spray pump leaking | 1. The stuffing box is not pressed tightly. 2. Packing seal failure | 1. Press the stuffing box 2. Replace the packing seal |

10 | Spray pump failure | 1. Impeller roller key 2. Impeller is stuck 3. Bearing is broken | Replace damaged parts |

11 | Mud piercing the cylinder liner flange | 1.The elm-resistant grinding disc was punctured 2.the seal of the roe deer wear-resistant disc failed. | Replace with new parts |

12 | The pump is running but cannot discharge mud. | 1.Empty pump 2.Suction pipe seal failure 3. Air enters the pump | 1.Raise liquid level 2.Tight seal 3.Circulating exhaust |

13 | The cylinder jack cannot be removed | 1. Rust 2. There are burrs 3. Deformation on impact. 4.Incorrect installation position | 1.Correction position 2. Use special tools 3.Clean before installing again,align position |

14 | Air bag in suction pipe leaks mud | Air bag torn | Replace with new parts |

15 | Guide plate wear | 1. Lack of oil 2. Surface strain 3. Lack of maintenance | 1.Improve lubrication 2.Clear surface strain |

16 | Guide plate gap exceeds standard | 1.Long service life without maintenance 2.Guide plate has low hardness | 1.Lower guide plate padding recovery required clearance 2.Replace with new guide plate |

17 | Bearing temperature rise>70℃ | 1.The oil pipe is blocked 2.Oily and dirty 3.There is foreign matter in the bearing raceway 4.Bearing wear | 1.Clean oil pipes 2.Change oil 3.Replace damaged bearings |

18 | Oil leakage in middle tie rod | 1.The seal of the root box fails 2.Cross head center up and down displacement | 1.Replace damaged bearings 2.Replace new seals and correct crosshead coaxiality |

19 | Power end knocking sound | 1.water hammer 2.Fastener loosening and collision 3.Guide plate gap is too large | 1.Improve inhalation performance 2.Inspect power end frame fasteners |

20

| Lubricating oil pump pressure reduced or no pressure | 1.Filter clogged 2.Oil pump damaged 3.The beautiful face is too low 4.The joint is loose or broken 5.The safety valve is faulty | 1.Clear filter 2.Replace oil pump 3.Replenish lubricating oil 4.Tighten or replace the joint 5.troubleshoot or replace it |

21 | Lubricating oil pump pressure rises suddenly | 1.Relief valve stuck or failed 2.The oil pipe is deformed or blocked 3.The pressure gauge is damaged 4. The sediment causes the oil to stick | 1.Clean and adjust relief valve 2.Repair the oil pipe or replace it 3.Replace the pressure gauge 4.Remove sediment |

22 | The middle tie rod fell off | 1. The connecting bolts are loose or broken 2. Cross head screw hole failure | 1.Replace with new bolts 2.Replace the cross head body 3.fasten |

23 | crosshead pin exit | Baffle bolt loosened

| 1.fasten 2.Replace with new bolts 3.A timely inspection |

24 | Local high temperature on pump frame | 1.The guide plate is strained or has burrs 2. Lack of lubricating oil 3. Replace the collar bolts and loosen the friction. | 1.Clean burrs or replace guide plate 2.Improve lubrication 3.Tighten or replace guide plate bolts |

25 | Gear pitting | 1.Lubricating oil cannot form an oil film 2.Overload operation | 1.Oil change 2. Use as required |

26 | Large pulley displacement | 1.Loose taper sleeve bolts 2.Taper sleeve not locked 3.Pressure plate bolt failure | 1.Fastening 2.reset 3.Locking taper sleeve |

27 | The clamp is not tight | 1.Taper grinding 2.Fixed frustum is damaged 3.Bad screw hole | Replace new |

General procedure for repairing a pump - replacing the piston

1. Inform the drilling floor to stop the pump.

2. Lock the motor on the drill floor/site, tell the electrical appliance to turn off the motor power, and tell the drill floor to turn on the pump for testing.

3. Close the mud water supply/drainage valve.

4. Open the pressure relief valve and keep it open.

5. Equip with a new set of piston and cylinder liner.

6. Remove the cooling water pipeline, use the disk pump to push the pull rod to the front, remove the connecting clip between the piston rod and the mud pump power end pull rod, and then retract the power end with the disk pump.

7. Use a hammer to open the threaded flange, and then use Pully's lifting tool with an inverted chain to lift the cylinder liner and piston combination and pull it out. Turn the pully bracket, lower it to the ground and untie it.

8. Take out the old cylinder liner sealing ring, clean and wipe it to check the condition of the resistant plate sealing surface, and install the new steel liner sealing ring.

9. Use the Puly tool to lift the new cylinder liner and piston assembly, and install it by reversing the procedure in step 6.

10. Install back the cooling water line.

11. Open the low-pressure mud and high-pressure mud pipeline valves, close the pressure relief valve, and drain

12. Open the motor lock and notify the drill floor.

Precautions for storage of drilling mud pumps

1. When the drilling pump is not used for a long time, it should be sealed.

2. Before sealing, the dirt should be carefully removed, all parts of the liquid end should be emptied, and washed and wiped clean with clean water.

3. Drain the lubricating oil from the bottom of the power end gearbox and remove the accumulated dirt at the bottom. Apply heavy oil to the processing surfaces of all bearings, crossheads, gears, piston rods, intermediate tie rods and other parts.

Apply grease to the machined surfaces of all parts of the liquid end.

The suction inlet and discharge outlet should be covered with blind plates.

7. The cross head hole end cover, back cover, sight hole cover, etc. should be closed tightly

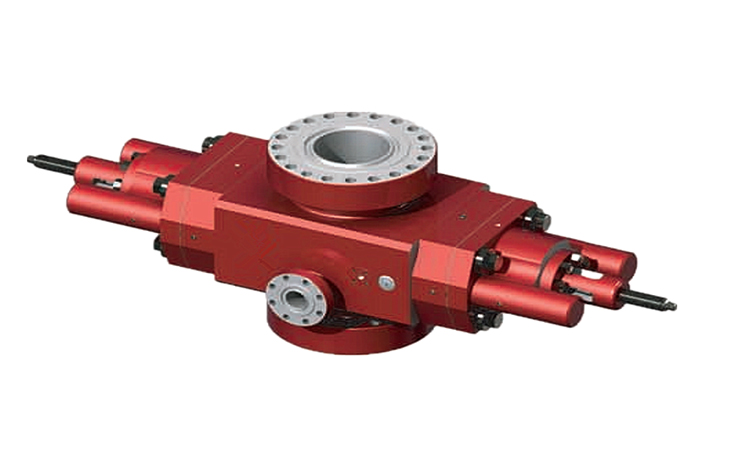

Sino Mechanical Equipment provides various oil drilling equipment, such as:Workover Rigs, drilling mud pumps and accessories,Annular BOP, Single Ram BOP and Double Ram BOP,BOP Stacks, Accumulator Unit, BOP Control System, Drilling Spools,Choke and Kill Lines,Hose Loops,etc. It is committed to developing and providing high-quality oil drilling equipment to meet the changing needs of customers and contribute more to the development of the petroleum industry.