Description

Overview of BOP Stacks

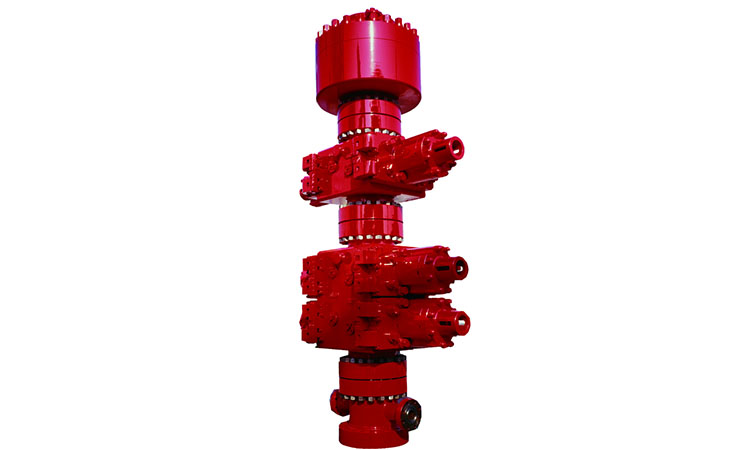

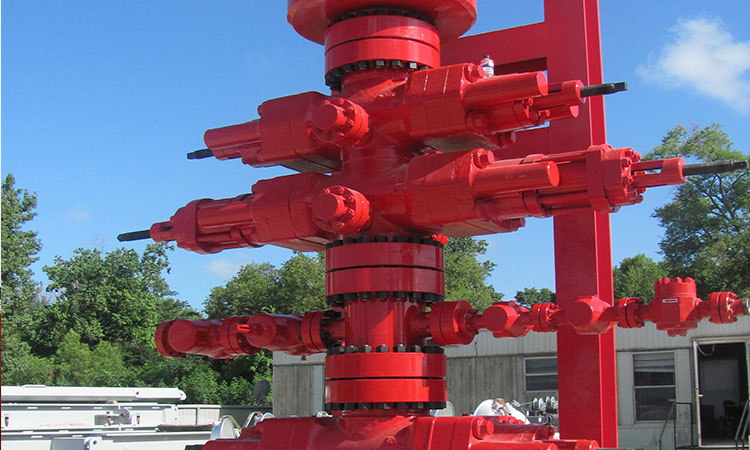

The BOP stack installation consists of annular BOP, single ram BOP, double ram BOP. Also, there can be a kill line valve and a choke line valve. The choke line valve is used to redirect the mud from the well bore to the choke manifold during a kick. The kill line valve is used to direct drilling fluid to the BOP during a kick.

BOP Stacks are one of two or more units used to seal, control and monitor oil and gas well pressure. BOP Stacks are mounted on the top of the casing head during drilling operations on every oil and natural gas drilling rig as well as the oil and/or natural gas well. BOP Stacks are safety equipment designed to prevent uncontrolled flow of formation fluids during drilling and completion operations.

The blowout preventer unit is a new generation of well control equipment developed by our company, which can meet the well control process requirements of high pressure oil and gas drilling.

When the BOP is applied on site, it can be used in multiple combinations according to the needs, including rotary BOP, ram BOP, double ram BOP, annular BOP and four-way etc. Generally, the upper part is a universal BOP, the middle is a variable-diameter ram BOP, and the bottom is a shear ram BOP, etc. There are many different combinations according to the needs of the site. Various blowout preventer combinations are collectively referred to as the blowout preventer group (BOP).

The BOP Stacks are controlled by a device called the accumulator unit, or BOP Control System. This unit can be operated remotely, using a panel located on the rig floor, or by personnel on the ground, using duplicate controls on the accumulator itself.

The application of well control technical measures in oil drilling construction can solve the safety problems of oil drilling, promote the improvement of oil drilling construction quality, and help complete oil drilling tasks safely and smoothly. Therefore, it is necessary to take well control technical measures and apply well control equipment to improve the safety of oil drilling.

Well control technical measures for drilling are to ensure the safety of oil drilling construction, use well control devices and equipment to strengthen safety management in the process of oil drilling construction, improve the safety of oil drilling construction, and prevent blowout and blowout out of control accidents. Well control equipment is a set of special equipment, instruments and tools for pressure control technology, including well control wellhead devices, well control manifolds, blowout prevention tools in drilling tools, drilling fluid gas separators, and automatic drilling fluid filling devices for tripping out etc. Combined with various monitoring devices and systems, the liquid level of the circulation tank is monitored and alarmed to ensure the normal circulation of the drilling fluid and prevent the occurrence of accidents in the tank, which will cause environmental pollution. The function of well control equipment is to prevent the occurrence of blowout accidents, make the pressure of the wellbore fluid column greater than the pressure at the bottom of the well, and prevent the fluid in the well from ejecting from the wellhead, which will affect the smooth progress of oil drilling. When the overflow is found in time and there is a sign of blowout, take measures to shut down the well immediately to prevent accidents. The blowout can be quickly controlled to prevent serious out-of-control blowout accidents. To deal with complex oil drilling accidents, if there is a serious out-of-control blowout, fire extinguishing and other operations can be started to prevent the accident from expanding and causing huge economic losses to oil drilling.

Features of BOP Stacks

Annular BOP:

1. The pressure-bearing parts are made of high-quality alloy steel, which has good strength and impact toughness.

2. Models with steam inlets for extremely cold areas.

3. The rubber core has a large amount of rubber storage, small frictional resistance when opening and closing, and strong well pressure sealing ability.

4. Well treated surfaces for high corrosion resistance.

5. The sealing rubber core can be interchanged with the rubber core of the same type of foreign blowout preventer.

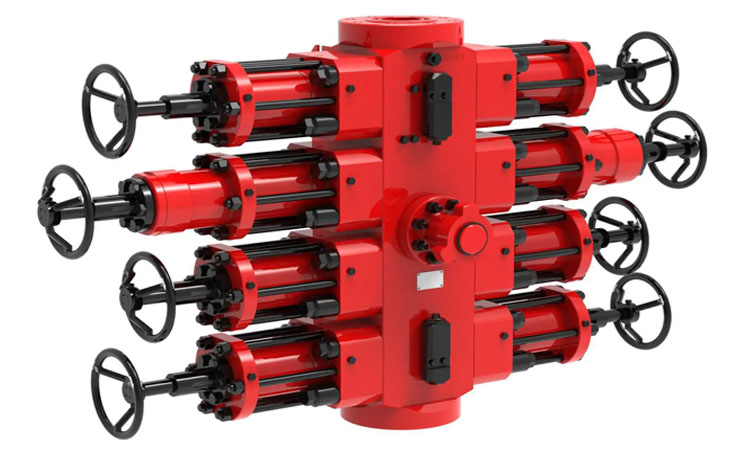

Single Ram BOP and Double Ram BOP:

1. The pressure-bearing parts are forgings, which have good strength and impact toughness.

2. Advanced sealing ensures reliability under ultra-high pressure.

3. Compact bonnet cylinder hydraulically driven for easy access to Ram.

4. Compatible with pipe/variable/shear Ram.

5. The ram rubber core has abundant reserves and adopts self-sufficient sealing.

6. All parts in contact with well fluid inside the high-sulfur-resistant blowout preventer are surfacing with high-nickel-based alloys, which can achieve the highest level of anti-H2S and CO2 effects (for customers to choose).

BOP Stack consist of

Annular BOP

Single Ram BOP

Double Ram BOP

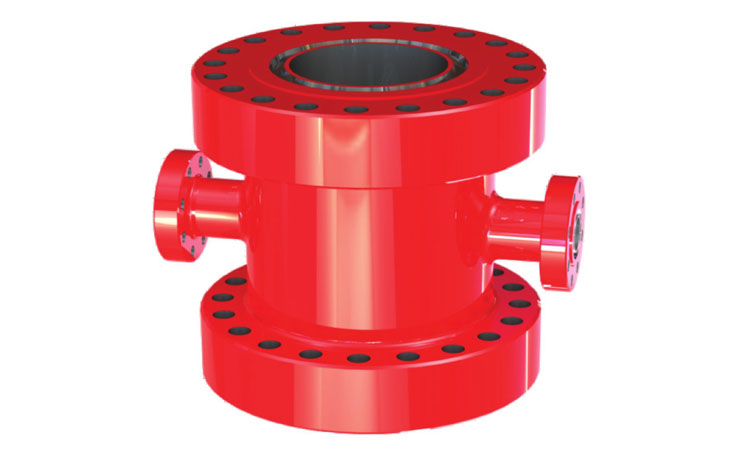

Drilling Spool

Choke and Kill Manifold

Accumulator Unit

Applications of BOP Stacks

1. The main purpose of the BOP Stacks is to control the wellhead pressure during drilling and workover operations. When overflow or kick occurs in the well, the wellhead can be closed quickly and in time to prevent blowout accidents.

2. During the oil drilling construction process, use well control equipment to control the entire oil drilling construction process to ensure the safety of oil drilling and improve the quality of oil drilling construction. Apply advanced oil drilling technology and technical measures to solve the difficult problems of well control and better complete oil drilling construction tasks.

3. Use various control systems to control and manage well control equipment, improve the operating efficiency of well control equipment, and achieve the effect of well control. In the field drilling construction process, there are usually three types of control systems, electric control, hydraulic control and air control. Each control system has its own characteristics. For land drilling construction, it is more suitable to choose hydraulic control and air control systems to achieve the expected control effect. The air pressure control system uses compressed gas, which is filtered and distributed to each gas exchange valve through the main valve of the gas source, to automatically control the well control equipment to achieve the effect of well control. The signal is transmitted remotely through the pneumatic pressure transmitter to realize automatic control, and the data signal is transmitted to the drilling information system to achieve the effect of automatic drilling construction and reduce the incidence of various accidents.

Price of BOP Stacks

The BOP Stacks Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price BOP Stacks. If you are looking for BOP Stacks or BOP Stacks spares, please kindly contact us to get the latest BOP Stacks price.

BOP Stacks Supplier

Sino Mechanical, as a BOP Stacks manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of BOP Stacks. We are global BOP Stacks supplier. We offer a wide range of drilling equipment and have BOP Stacks for sale. We also provide OEM services. We design, manufacture, and sell BOP Stacks for your drilling applications. If you want to know latest BOP Stacks price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of BOP Stacks

Nominal Size: 7-1/16", 9", 11", 13-5/8", 16-3/4", 20-3/4", 21-1/4".

Working Pressure: 2,000Psi, 3,00Psi, 5,00Psi, 10,00Psi, 15,000Psi

Temperature Class of Materials: T75, T20, T0

Temperature Grade of Non-metallic Seals: A~D (-46℃~121℃)

Performance Level: PR1, PR2