Description

Overview of Coiled Tubing BOP

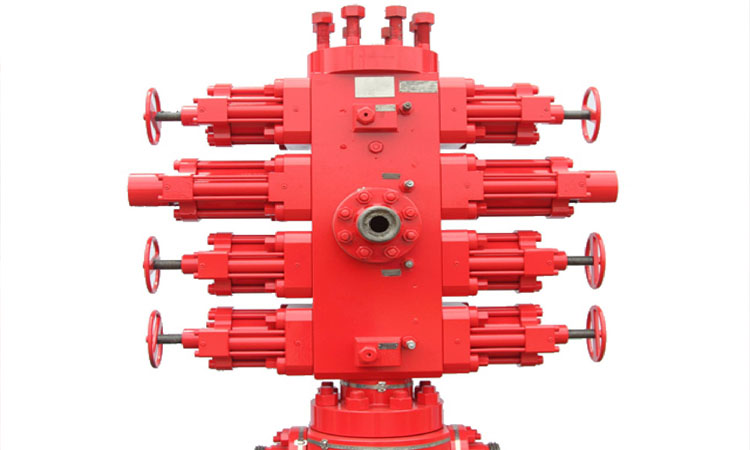

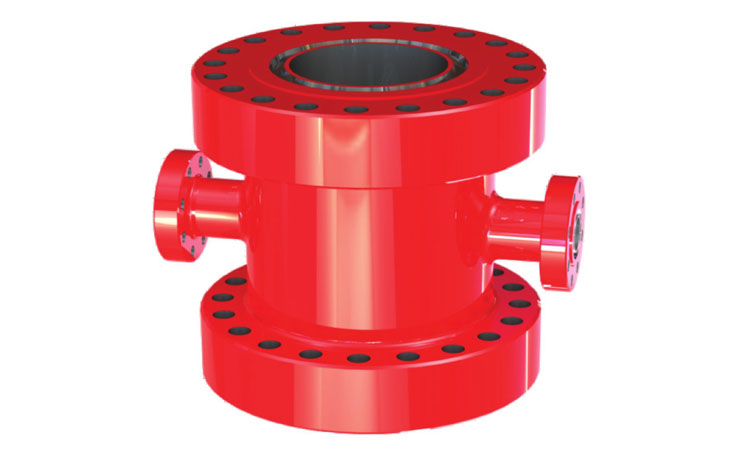

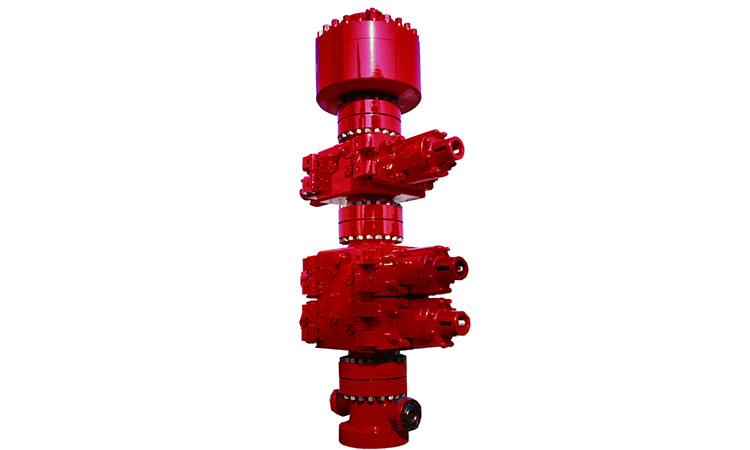

Coiled Tubing BOP is an important well control unit against overflow (oil, gas and water) and well blowout, thus to avoid resource waste, protect equipment and human safety. The Coiled Tubing BOP (Quad BOP) is designed to provide wellbore isolation and positive protection against blowouts and to secure the well in emergencies.

The Coiled Tubing BOP is suitable for coiled tubing sand washing, well washing, oil testing, gas lift induced blowout, liquid drainage, plugging removal, drilling and grinding, staged fracturing, drag acidizing, cable operation, gas well completion, fishing Falling objects, drilling and other operations. The Coiled Tubing BOP is mainly composed of side-opening door blowout preventer box, blowout preventer pipe, hydraulic control four-ram blowout preventer, blowout joint, wellhead adapter flange or joint and other components.

Features of Coiled Tubing BOP

1. The Coiled Tubing BOP is equipped with blind rams, shear rams, slip rams, pipe rams and blind shear ram, which feature simple operation and easy maintenance.

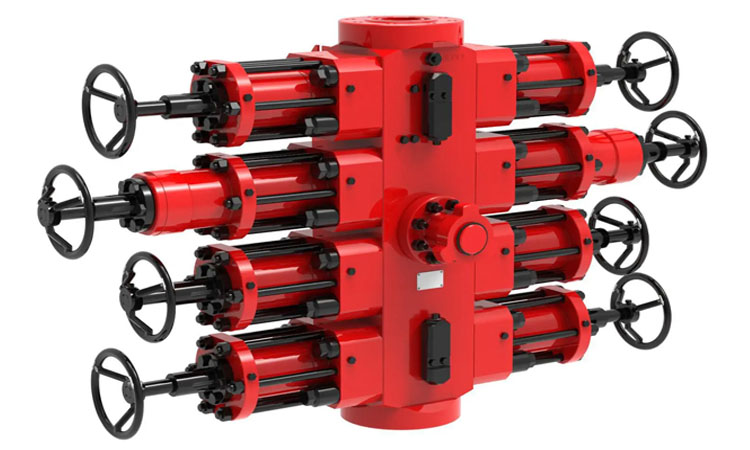

2. Hydraulic drive, rapid closure time. Ram open/ close and replacement adopt the same internal hydraulic passage, easy and safe to operate.

3. Equipped with a ram stroke indicator rod, which is convenient for displaying the working status of the ram.

4. Equipped with manual locking, high safety factor and high reliability. Ram position indicator rod is designed to indicate ram position during operation. Ram running indicator rod is designed to indicate ram position during operation.

5. Innovative shear actuator eliminates the impact of wellbore pressure on shearing process.

6. Open/close sign on the hand wheel is easy to identify.

7. Multicouplings allow fast and accurate engagement and disengagement of hydraulic control lines.

8. Suitable for high pressure wellhead and H2S working environment.

Applications of Coiled Tubing BOP

The Coiled Tubing BOP is an indispensable part of the coiled tubing operation. When overflow, well kick and blowout occur, the Coiled Tubing BOP can shut down the well and perform well killing operations quickly to prevent blowout and re-establish the oil and gas well pressure control.

Price of Coiled Tubing BOP

The Coiled Tubing BOP Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Coiled Tubing BOP. If you are looking for Coiled Tubing BOP or Coiled Tubing BOP spares, please kindly contact us to get the latest Coiled Tubing BOP price.

Coiled Tubing BOP Supplier

Sino Mechanical, as a Coiled Tubing BOP manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Coiled Tubing BOP. We are global Coiled Tubing BOP supplier. We offer a wide range of drilling equipment and have Coiled Tubing BOP for sale. We also provide OEM services. We design, manufacture, and sell Coiled Tubing BOP for your drilling applications. If you want to know latest Coiled Tubing BOP price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Coiled Tubing BOP

MODEL | MAIN BORE | RATED PRESSURE (PSI) | MAX. HYDRAULIC PRESSURE (PSI) | TUBING SIZE | WEIGHT (LBS) | DIMENSIONS |

3 1/16"-10K | 3 1/16" | 10,000 | 3,000 | 1"- 2" | 1,918 | 58.50"×19.10"×28.68" |

4 1/16"-10K | 4 1/16" | 10,000 | 3,000 | 1"-2 3/8" | 2,416 | 77.15"×18.18"×32.24" |

4 1/16"-15K | 4 1/16" | 15,000 | 3,000 | 1"-2 3/8" | 2,520 | 77.15"×19.05"×32.89" |