What is a BOP control system

What is a BOP control system?

The blowout preventer control system (Accumulator Unit) is the power device for opening and closing the blowout preventer and kill valve. It must not only provide hydraulic oil with sufficient pressure and displacement, but also store this hydraulic energy in normal times. Once needed, the hydraulic oil can be accurately and quickly delivered to the cylinders of the blowout preventer and hydraulic valve through control valves. , thereby achieving the purpose of switching.

Control system composition and layout

Hydraulic blowout preventers are equipped with a control system, and the switch of the blowout preventer is realized through its control. The required pressure is provided by the control system. The function of the control system is to prepare and store a sufficient amount of pressure oil in advance and control the flow direction of the pressure oil so that the blowout preventer can be opened and closed quickly. When the pressure oil is used up, the oil volume decreases, and the oil pressure drops to a certain level, the control system can automatically replenish the oil storage to keep the hydraulic oil within a certain high-pressure range.

Composition of blowout preventer control system

The control system consists of an accumulator unit (remote console), a remote control device (driller's console), an auxiliary remote control device, and connecting manifold. Some are also equipped with auxiliary remote control devices.

Accumulator unit

The accumulator unit, also known as the remote console, is a hydraulic device that prepares, stores and controls pressure oil. It consists of oil pumps, accumulator devices, valves, pipelines, oil tanks and other components. Operate the reversing valve to control the input of pressure oil into the oil chamber of the blowout preventer, directly causing the wellhead blowout preventer to realize switching action. The accumulator unit is installed 30m away from the wellhead side.

Remote control device

The remote control device is a remote control system that controls the action of the reversing valve on the accumulator unit, which indirectly makes the wellhead blowout preventer switch action. The remote control device is installed near the driller's post on the drilling platform. Also known as the driller's console.

Auxiliary remote control device

The auxiliary remote control device is placed in the duty room as a backup remote control device for emergencies. According to the different control methods of the remote control blowout preventer switch and reversing valve, that is, according to the different pilot methods, the control device is divided into hydraulic transmission remote control, pneumatic transmission remote control, electric transmission remote control, that is, hydraulic control liquid type, pneumatic control liquid type, and electronic control. Three types of liquid type. At present, most of the control devices used in onshore drilling are pneumatic-hydraulic control systems.

The working process of the pneumatic-hydraulic control system

The working process of the pneumatic-hydraulic control system is divided into three parts: preparation of hydraulic energy, pressure adjustment of pressure oil, flow direction control, and pneumatic remote control.

1. Preparation of hydraulic energy

The hydraulic oil in the tank enters the electric pump or air pump through the oil inlet valve and filter, and is pumped into the energy accumulator by the electric pump or air pump. The accumulator is pre-charged with nitrogen and the pressure is 7MPa. The electric pump pumps the pressure oil above 7MPa. Enter the bottle, the amount of oil in the bottle gradually increases, the oil pressure rises, and the nitrogen in the capsule is compressed until the pressure in the bottle reaches 21MPa. At this time, the volume of nitrogen in the capsule accounts for about 1/3 of the volume of the cylinder.

2. Pressure regulation and flow direction control of pressure oil

After the pressure oil of the accumulator enters the control manifold, one path is controlled by the pneumatic pressure reducing valve and sent to the reversing valve that controls the annular blowout preventer; the other path is controlled by the manual pressure reducing valve and then passes through the bypass valve (two-position three valve) is transmitted to the reversing valve manifold that controls the gate blowout preventer and hydraulic valve, and the handle of the reversing valve is operated to realize the opening and closing of the blowout preventer.

3. Air pressure remote control

After the compressed air passes through the water separation filter and oil mist device, it is transported to each air reversing valve (three-position four-way reversing slide valve or rotary valve) through the automatically resetting main air source valve (two-position three-way reversing valve). ), controls the action of the two-position cylinder on the accumulator device, thereby controlling the corresponding reversing valve handle and indirectly controlling the blowout preventer switch.

Principles for selecting the amount of liquid stored in the energy accumulator

When selecting a control device, its energy accumulator should be able to ensure that it only relies on the effective oil discharge volume of the energy accumulator itself (the amount of oil discharged when the cylinder oil pressure drops from 21MPa to 8.4MPa) when the pump is stopped and no oil is replenished. 2/3 can meet the need to close all control objects once. When the accumulator inflation pressure is too low, the effective oil discharge volume of the accumulator decreases. When there is no air pressure, the accumulator can only hold oil. If it cannot store pressure, there will be no high-pressure oil to be discharged, and the blowout preventer switch cannot be controlled.

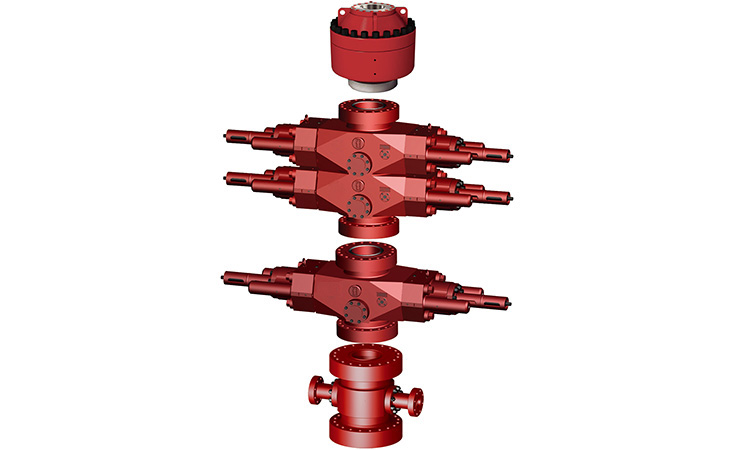

Supplier of BOP Control System

Sino Mechanical Equipment provides various oil drilling equipment, such as: Annular BOP, Single Ram BOP and Double Ram BOP,BOP Stacks, Accumulator Unit, BOP Control System, Drilling Spools,Choke and Kill hoses, Hose Loops, drilling mud pumps and accessories, etc. It is committed to developing and providing high-quality oil drilling equipment to meet the changing needs of customers and contribute more to the development of the petroleum industry.