Description

Overview of Mud Gas Separators

The mud gas separator (poor boy degasser) is primarily used to separate and safely vent large pockets of free gas, that may include toxic gases such as hydrogen sulfide.

The mud gas separator (poor boy degasser) designed and manufactured by Sino Mechanical is the main equipment used to separate gas and liquid from the gas-bearing mud in the well during the drilling process. When the drilling fluid has gas invasion, its specific gravity and viscosity deviate greatly, which cannot meet the drilling requirements. In severe cases, if it is not dealt with in time, it will cause a well kick or even a blowout accident. The combined use of the mud gas separator (poor boy degasser) and the electronic ignition device can ensure the smooth progress of the drilling process.

Mud gas separator (poor boy degasser) Atmospheric pressure anti-hydrogen sulfide drilling fluid mud gas separator (poor boy degasser) is made of high-quality materials. Mud gas separator (poor boy degasser) can effectively prevent the erosion of harmful gases and ensure the safe production of man and machine.

The mud gas separator (poor boy degasser) is used in conjunction with the choke manifold to separate free gas from the drilling fluid. It can be applied to under balanced drilling and drilling fluid containing hydrogen sulfide gas.

Features of Mud Gas Separators

1. The Mud Gas Separators adopts bottom drainage to control the working liquid level. This ensures that the liquid level in the separator is constant and at the same time solves the problem of sand accumulation in the tank.

2. There is a special channel for gas separation in the Mud Gas Separators tank. The gas is evacuated smoothly, which improves the gas treatment effect.

3. The Mud Gas Separators adopts the combination of centrifugal separation, physical impact separation, vacuum separation and other separation technologies. The gas separation effect is ensured.

4. A buffer device is installed at each corner of the liquid supply pipe of the Mud Gas Separators and a replaceable impact-resistant baffle is installed. Regular inspection and replacement can be carried out according to the wear condition, which prolongs the service life of the equipment.

5. The anti-sulfur type Mud Gas Separators is manufactured and processed with special materials as a whole. It can completely prevent the hydrogen sulfide gas in the gas from damaging the equipment.

6. Mechanical separation, zero energy consumption

7. Special material, corrosion resistance

8. Optimized equipment structure, small footprint and beautiful appearance.

9. The field use feedback effect is good, less vulnerable parts, high cost performance

10. In terms of Mud Gas Separators material selection, the reliability of material quality is guaranteed

11. Grinding, sandblasting, epoxy zinc-rich primer, epoxy miracic iron intermediate paint, and polyurethane topcoat for the whole equipment. The high-pressure airless spraying construction improves the anti-corrosion and aesthetics of the equipment.

12. U-shaped tube design is adopted to drain liquid and sewage at the bottom. The liquid level is constant. It is not easy to accumulate sand in the tank, and it is easy to remove. Replaceable impact-resistant flanges are installed at each corner of the liquid supply pipe, which can be replaced regularly according to the wear and tear to prolong the service life of the equipment.

13. Baffle plates within vessel creates Maximum removal of free gas.

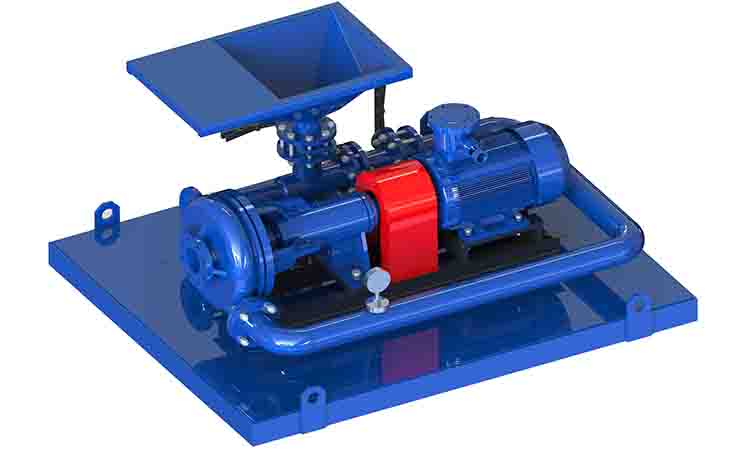

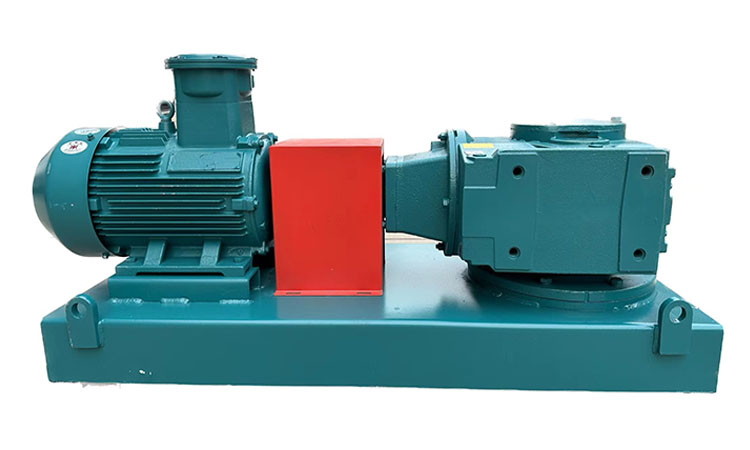

14. Skid-mounted design enables easy transportation, rig-up and rig-down.

15. Designed, manufactured and tested in accordance with API & ISO standards.

Applications of Mud Gas Separators

Mud Gas Separator (Poor Boy Degasser) is engineered specifically for onshore drilling operations. Mud Gas Separators are used to remove large bubbles containing air and natural gas in drilling fluid. Primary degassing treatment is carried out after the operation, so as to prevent blowout and well kick.

Working principle of Mud Gas Separators

The gas-containing mud returned from the confluence pipe of the cut-off manifold enters the separation tank through the inlet manifold of the Mud Gas Separators. First impact the splitter tube in the middle to disperse the mud, which falls to a series of baffles. The mud flows from top to bottom on the baffle, resulting in turbulent flow. According to the principle of liquid gas settling, decompression and expansion, part of the gas is separated from the mud. After multiple baffles, the area where the mud flows through the baffle increases, and the mud separates into thin layers on the baffle. Bubbles are exposed on the surface of the mud, allowing the gas to separate from the mud. The free gas is discharged to a safe area through the exhaust pipe on the top of the tank. The degassed mud is conveyed from the outlet to the mud distributor, vibrating screen or skimming tank.

Types of Mud Gas Separators

1. Class A: bottom-covered Mud Gas Separators

The bottom of the gas storage tank is closed, and the drilling fluid returns to the circulation tank through a U-shaped pipeline. The height of the drilling liquid level in the degassing tank can be controlled by increasing or decreasing the height of the U pipe.

2. Type B: Open bottom Mud Gas Separators

The separator tank is bottomless and the lower half is submerged in the drilling fluid. The liquid level in the tank is controlled by the submerged depth of the bottom. This kind of separator is called "poor boy" , which shows its simplicity.

Generally, the bottom-sealed Mud Gas Separators is commonly used.

Price of Mud Gas Separators

The Mud Gas Separators Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Mud Gas Separators. If you are looking for Mud Gas Separators, please kindly contact us to get the latest Mud Gas Separators price.

Mud Gas Separators Supplier

Sino Mechanical, as a Mud Gas Separators manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Mud Gas Separators. We are global Mud Gas Separators supplier. We offer a wide range of drilling equipment and have Mud Gas Separators for sale. We also provide OEM services. We design, manufacture, and sell Mud Gas Separators for your drilling applications. If you want to know latest Mud Gas Separators price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Mud Gas Separators

Design Pressure: 1.6-6.4 Mpa

Capacity: 180-360m³/h

Wall Thickness: 10mm

Outlet for Liquid: 10”

Payment Terms: TT

The working pressure is determined according to the customer's on-site working conditions.

The processing capacity depends on the customer's drilling depth.

The authentication method depends on the customer's use environment.

Structure type: vertical or horizontal, etc., depends on the customer.