Mud Agitators of Sino Mechanical Equipment supplied to Middle East customers is ready for shipment

Mud Agitators of Sino Mechanical Equipment supplied to Middle East customers is ready for shipment.

Features of mud agitator from Sino Mechanical Equipment

1. Efficient mixing ability

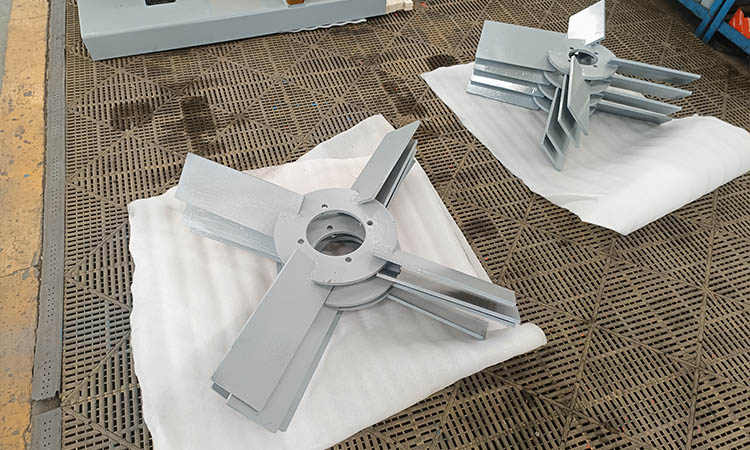

Fast and uniform mixing: Adopt optimized blade design (such as propeller type, turbine type, etc.) to ensure that the solid particles, chemical additives and liquid in the mud are fully mixed to avoid precipitation or stratification.

Adapt to different viscosities: It can handle a variety of fluids from low viscosity (such as clear water-based mud) to high viscosity (such as oil-based or high-density mud).

2. Wear and corrosion resistance

Wear-resistant materials: Blades and stirring shafts often use high-hardness alloys (such as nickel-based alloys) or rubber coatings to resist the wear of solid particles in the mud (such as barite, drill cuttings).

Anti-corrosion design: For corrosive muds (such as salt-containing or acidic media), stainless steel (such as 316L) or epoxy resin coatings are used.

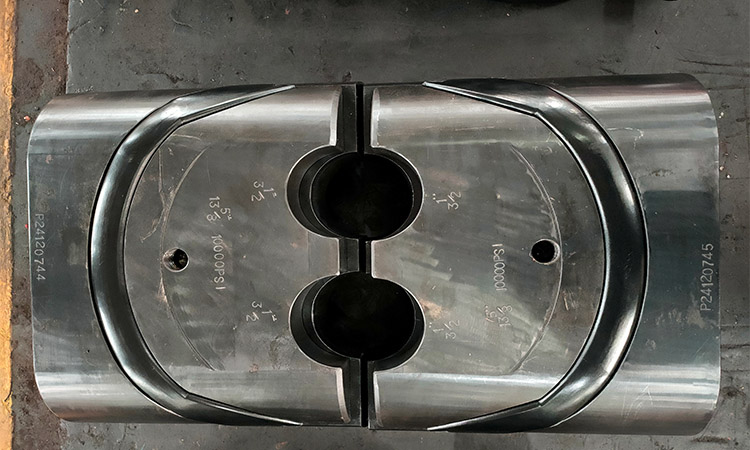

3. Structural design and sealing

Heavy-duty bearing support: withstands high torque and axial loads, extending equipment life.

Dynamic sealing system: uses mechanical seals or packing seals to prevent mud leakage and adapt to high-pressure and high-temperature conditions (such as deep wells or high-temperature formations).

4. Flexible power configuration

Motor or hydraulic drive: select electric (explosion-proof motor) or hydraulic motor according to well site conditions, with a wide power range (usually 5-30kW).

Frequency conversion control: Some models support speed regulation to adapt to different mixing requirements (such as low speed to prevent impact during startup, high speed during mixing).

5. Adapt to harsh working conditions

High temperature and high pressure resistance: designed for high temperature (>100℃) and high pressure environments (such as high-pressure wellbore conditions).

Explosion-proof design: meets API or ATEX explosion-proof standards in explosive gas environments (such as oil and gas wells).

6. Convenient maintenance

Modular design: blades, shafts and other components can be quickly disassembled and replaced to reduce downtime.

Lubrication system: Some models are equipped with automatic lubrication devices to reduce maintenance frequency.

7. Diversity of application scenarios

Mud tank matching: usually installed in the mixing tank, storage tank or sedimentation tank of the mud circulation system.

Special needs adaptation: such as shear cementing mud (high shear mixer) or nanomaterial dispersion.

8. Safety and environmental protection

Splash-proof design: reduce mud splashing during mixing and protect the working environment.

Low noise operation: optimize the mechanical structure to reduce noise pollution.

9. Standardization and customization

Comply with API standards: such as API 13C requirements for drilling fluid equipment.

Customization options: adjust parameters according to well depth, mud type (water-based/oil-based/synthetic-based) or special additives.

Classification of mud agitators

1. Classification by drive mode

Electric agitator

Driven by electric motor, it has a simple structure and easy maintenance, and is suitable for drilling sites with stable power supply.

Commonly used in onshore drilling or fixed platforms.

Hydraulic agitator

Driven by a hydraulic motor, it has large torque and wide speed range, suitable for high-viscosity mud or harsh working conditions (such as offshore platforms).

Good explosion-proof performance, suitable for flammable environments.

Mechanically driven agitator

Directly connected to the diesel engine/generator through a drive shaft, it is now less used.

2. Classification by installation method

Vertical agitator

The agitator shaft is installed vertically, occupies a small space, and is suitable for compact mud tanks or small drilling systems.

Horizontal agitator

The agitator shaft is installed horizontally, with a large mixing range, and is often used in large mud circulation systems or high-capacity mud tanks.

3. Classification by agitator blade type

Propeller type (axial flow)

Produces axial flow, uniform mixing, suitable for low-viscosity mud.

Turbine type (radial flow)

Produces strong shear force, suitable for high-viscosity or solid-phase mud.

Paddle type

Simple structure, used for conventional mixing, but low efficiency.

Combined type

Combined with a variety of blade designs, it takes into account both mixing and suspension functions.

4. Classification by functional use

Main mud agitator

Used for mixing the main body of the mud tank to ensure stable drilling fluid performance.

Shear agitator

High-speed rotation, specially used for rapid dispersion and dissolution of materials such as polymers and additives.

Anti-settling agitator

Runs at a low speed to prevent the precipitation of solid phase particles such as barite.

5. Classification by working environment

Land-based agitator

Standard design, focusing on cost and maintenance convenience.

Offshore platform agitator

Anti-corrosion and explosion-proof design, suitable for high humidity and high salt environments.

Polar/high temperature environment agitator

Special materials (such as low-temperature steel) and sealing technology.

6. Special type

Variable frequency speed agitator

The speed is adjusted by the frequency converter to adapt to different working conditions.

Explosion-proof agitator

Complies with API or ATEX standards and is used in flammable and explosive environments.

Selection of mud agitators

Mud properties: viscosity, solid content, additive type.

Tank size: volume and depth determine the stirring power and blade size.

Environmental requirements: explosion-proof, corrosion-resistant, temperature adaptability.

Energy efficiency ratio: select electric or hydraulic drive according to the working conditions.

Different types of agitators can be used in combination (such as main agitator + anti-settling agitator) to ensure uniform and stable mud performance. In practical applications, it is necessary to refer to industry standards such as API 13C for design and selection.

Mud agitator supplier

Sino Mechanical Equipment is a reliable oil drilling mud agitator supplier in China. The core features of oil drilling mud agitators are designed around efficient mixing, durability and adaptability to working conditions, aiming to ensure the stability of drilling fluid and the continuity of drilling operations. When selecting, factors such as mud properties, well depth conditions and power requirements need to be considered comprehensively.