What Is A Wired Drill Pipe? The Rise and Advantages of Wired Drill Pipe

Global oil drilling activities are increasingly shifting towards challenging operational environments to extract more petroleum. With advancements in drilling techniques such as horizontal drilling, this has become feasible. The petroleum drilling activities in North America are continuously on the rise, primarily conducted in harsh environments, either offshore or onshore, to extract shale oil and natural gas. Shale oil is becoming a major source of petroleum consumption in North America, with numerous companies engaged in petroleum exploration, drilling, and production activities. Additionally, in Canada, the Arctic region is increasingly becoming a significant source of petroleum discoveries, with many companies extracting oil in challenging operational environments. The increased drilling activities are conducted while ensuring operational safety to avoid oilfield leaks and threats to the environment.

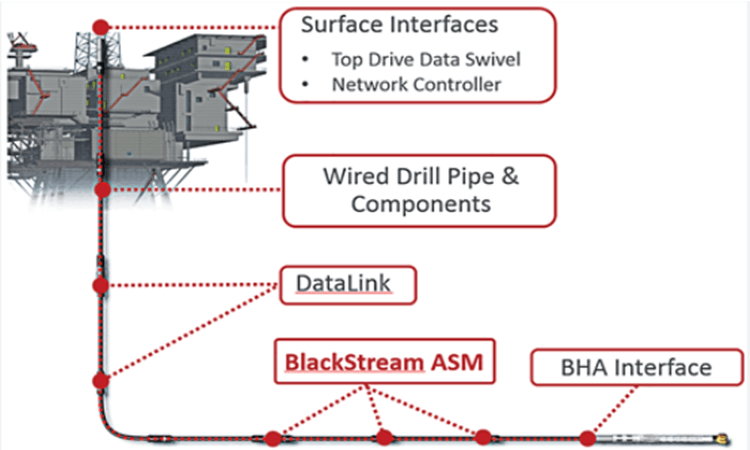

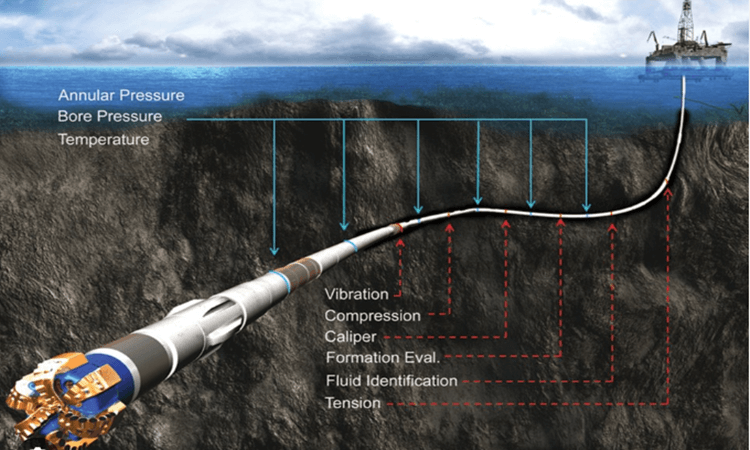

Against the backdrop of these changing market demands, the petroleum industry's need for more advanced drilling technologies is growing. This demand has led to the emergence of a pressing need for "Wired Drill Pipe" (WDP). A Wired Drill Pipe is an innovative tool used in oil and gas drilling. Unlike traditional drill pipes, a Wired Drill Pipe is equipped with sensors, communication devices, and data transmission technology embedded internally. This configuration enables real-time data collection and transmission capabilities. The embedded sensors monitor various drilling parameters such as the rotation speed of the drill bit, drilling pressure, well depth, etc., and transmit this data to the surface or a remote location.

Wired Drill Pipe offers the following advantages:

Real-time data transmission and monitoring: In harsh environments, WDP provides real-time drilling parameters and geological information, enabling operators to make timely decisions and reduce potential risks.

Remote monitoring and adjustments: Due to real-time data transmission, WDP allows remote monitoring of the drilling process, which is crucial for projects conducted in remote areas, reducing the need for personnel on-site.

Automation control: The integrated automation control system in WDP makes the drilling process more intelligent, enabling more precise control in complex geological conditions.

Reduced accident risks: Through real-time monitoring and intelligent control, WDP helps identify and address potential issues promptly, thereby lowering the risk of underground accidents.

In summary, Wired Drill Pipe holds a significant advantage in meeting the real-time monitoring and control requirements of drilling in harsh operational environments. It provides the petroleum industry with a more advanced solution for drilling challenges.