Description

Overview of Mud Tanks

Mud Tanks can be divided into vertical mud tank and horizontal mud tank. Sino Mechanical is a manufacturer of mud tanks, which can design and produce drilling mud tanks of various specifications. Our mud Tanks include solid control system mud tank, skid-mounted vehicle mud tank, buried tank, etc. The mud tanks we produce are often used to install solid control equipment, store mud, configure mud, etc., to meet the requirements of drilling solid control systems, mud stations, and solid-liquid separation systems. Mud tanks can be divided into metering tanks, supply tanks, cooling tanks, low-temperature drilling mud tanks, trailer-mounted vehicle-mounted mud tanks, etc. according to their uses.

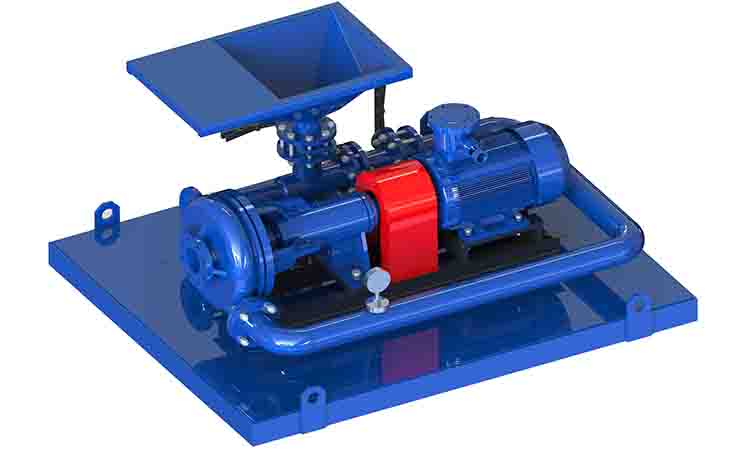

The supporting equipment on the mud tank generally includes drilling fluid shale shaker, vacuum degasser, desander, desilter, sand and desilter integrated machine, liquid-gas separator, agitator, sand pump, shear pump, centrifuge , electronic ignition device, mixing funnel, jet mixing device, mud gun, etc.

Slurry tanks often use corrugated board to make the side walls stronger. The steel is sandblasted first, and the paint we use is the gold epoxy zinc-rich paint coating of the Kansai brand in Japan. The thickness of the first layer is 75μ, and the epoxy medium is twice. The thickness is 250μ, and the polyurethane topcoat is twice. And the thickness of the outside of the tank is 70 μ. Spray 2 coats inside the can as above. The mud tank is usually installed with an ISO standard interface for easy lifting from the tank roof. Sino Mechanical can design and manufacture all mud tanks of the mud circulation system, including supply tanks, mud storage tanks, mixing tanks, circulation tanks, etc.

Features of Mud Tanks

1. The surface of mud tank and corridors are made of non-slip steel plates and non-slip strip mesh panels. And the tank surface railings are made of square steel pipes, which are barrier-free and fold able structures.

2. The tank surface of the mud tank circulation system is equipped with clean water pipelines to clean the tank surface and equipment. The tank surface mesh plate is treated with zinc dipping.

3. The tank ladder adopts channel steel as the main body and uses non-slip strip mesh as the pedal. The double side guardrails are equipped with safety hooks.

4. Oil drilling mud tanks are equipped with standard sand-proof and rain-proof shelters. And the heating insulation pipelines are installed inside the tanks.

5. A reasonable supporting scheme can be designed according to customer requirements.

6. The tank body is welded with steel plates and profiles. And the weld seam can be inspected for flaw detection and tank pressure test.

7. The mud tank is equipped with manholes, ladders, guardrails, etc., which are convenient for the staff to operate.

8. The tank spray paint adopts heavy marine anti-corrosion paint with high anti-corrosion and high wear resistance.

9. The mud tank adopts electrical centralized control, and its equipped manifolds are all built-in manifolds, which are convenient for installation, disassembly and transportation. In polar low temperature regions, the tank is equipped with heating system and insulation system.

10. The layout of solids control equipment is reasonable, reaching the five-stage purification standard (coarse screening, degassing, desanding, desilting, centrifugation), which further optimizes the mud performance.

11. The surface of the tank is made of galvanized steel grating, which has the characteristics of beauty, lightness and corrosion resistance.

12. The tank body is connected with a pneumatic union glass steel pipe, which has the advantages of convenient installation, beautiful appearance and reliable sealing.

13. Large tank capacity.

14. The water supply system realizes automatic control, and each tank or compartment can meet the requirement of uniform water supply at the same time.

15. Anti-corrosion. The surface strength of the tank is enhanced by using advanced technology and materials such as rust removal by wind and sand, spraying marine special paint, and ensuring the appearance and durability of the tank.

Applications of Mud Tanks

Through the recovery of drilling fluid mud tanks, the drilling fluid can be greatly purified. The horizontal traversing speed can be increased. The wear of mud pumps, drill pipes, and drill bits can be reduced. The mud materials can be saved, and drilling costs can be reduced. The environment can be protected. Mud tanks can bring considerable economic benefits to users benefit.

Price of Mud Tanks

The Mud Tanks Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Mud Tanks. If you are looking for Mud Tanks, please kindly contact us to get the latest Mud Tanks price.

Mud Tanks Supplier

Sino Mechanical, as a Mud Tanks manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Mud Tanks. We are global Mud Tanks supplier. We offer a wide range of drilling equipment and have Mud Tanks for sale. We also provide OEM services. We design, manufacture, and sell Mud Tanks for your drilling applications. If you want to know latest Mud Tanks price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Mud Tanks

Mud tanks | System effective volume(not including trip tank: 180m3. The solid control system adopt shaker,degasser,mud cleaner,centrfuge, 4 stages mud cleaning equipments. Main equipments are domestic famous-brand products which are in good quality and with long life and beautiful appearance, can meet the requirement of drilling fluid ciruclation,filling up,weighting up and to satify the technological requirement of trouble removal in particular cases and drilling for 4000m. Liquid gas separator with ignition device. |

Shaker Tank | Tank dimension: 14000×3060×2700mm |

Suction Tank | Tank dimension: 14000×3060×2700mm |

Mixing Tank | Tank dimension: 14000×3060×2700mm |

Reserve Tank | Tank dimension: 14000×3060×2700mm |