Description

Overview of Desanders and Desilters

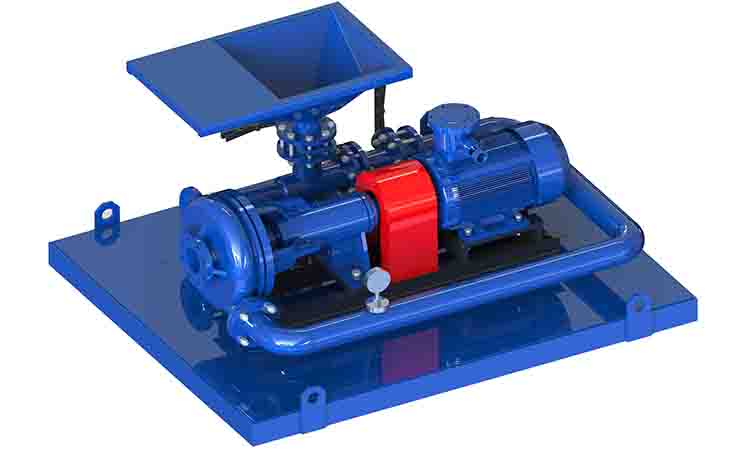

The drilling fluid desander is the second level solid control equipment of the drilling platform. It mainly removes 44~74μm solid phase particles.

Desander is a secondary solid control equipment for drilling fluid. According to the diameter of the cyclone, it is divided into a cyclone desander and a cyclone desilter. Generally, the combination of cyclones above 6″ is called desander. It is a secondary solid control equipment in drilling operations. Commonly used are 10″ and 12″ cyclones. It is mainly used to separate the particle size of 47-76μm in drilling fluid According to the processing capacity required by the customer, select several groups of cyclones to combine into a desander. Sino Mechanical cyclone desander is widely used in oil drilling and horizontal directional drilling for sand removal and separation.

In drilling solids control system, desander and desilter is usually called sand and desilter integrated machine. It is the combination of desander and desilter optimize the combination.

The desander with underflow shaker is also called mini desander cleaner which is applicable for both weighted and unweighted drilling mud, while traditional desander no underflow vibrating screen only for unweighted drilling fluids. And comparing with large size mud cleaner, the Mini Desander is cost-effective. For compact mud system used in HDD, CBM, water well drilling and mining project, Mini desander is an Ideal choice.

Drilling fluid desilter is a three-stage solid control equipment for drilling fluid. According to the diameter of the cyclone, it is divided into a cyclone drilling fluid desander and a cyclone drilling fluid desilter. Generally, the combination of cyclones below 6″ is called drilling fluid desilter. It is a three-stage solid control equipment in drilling operations. Commonly used are 5″ and 4″ cyclones, which are mainly used to separate the drilling fluid with a particle size of 15 Solid phase particles of -47μm. According to the size of the processing capacity required by the customer, select several groups of cyclones to form a desilter. Sino Mechanical swirling drilling fluid desilter is widely used in oil drilling and horizontal directional drilling flow desilting separation.

In the traditional configuration scheme of drilling solids control system, the drilling fluid desander and desilter are separately divided into two types of equipment for configuration. This requires more resources for these two separate equipment, including the length of the mud tank, power supply system, slurry pump, and maintenance. This increases the investment of the whole drilling solids control system. In order to optimize the system scheme and reduce the input cost, the desander and the desilter are combined into one set to form a desander and degasser (integrated machine for desander and desilter).

Features of Desanders and Desilters

The new drilling solid control system will further optimize the combination of solid control equipment. We are using a new type of double-layer or three-layer vibrating screen to replace the desilter (sand and desilter integrated machine). Under the premise of meeting the circulation requirements of various drilling fluids, the volume of the solid control system can be compressed. It makes the solids control system more compact, more energy-saving, more environmentally friendly and more efficient, thus completing a new round of equipment evolution and improving the level of modern drilling.

Features of Desilters

1. The cyclone is made of high wear-resistant polyurethane, which has a longer service life.

2. The connection method is clamp connection, which is convenient for installation and disassembly.

3. Compact structure, small footprint, flexible handling, etc.

4. Depending on the processing capacity, 1, 2 or 3 4” or 5” desilter cyclones can be flexibly selected.

5. The size and quantity of cyclones can be flexibly configured to better meet customer customization requirements

6. Desander Options with shaker and without shaker for flexible application.

7. Desander Cyclone PU material with better Abrasion resistance.

8. No under shaker design structure compact and assembly flexible.

9. Mini desander cleaner with shaker for both weighted / unweighted mud in various drilling.

Features of Desanders

1. Desander Options with shaker and without shaker for flexible application.

2. Desander Cyclone PU material with better Abrasion resistance.

3. No under shaker design structure compact and assembly flexible.

4. Mini desander cleaner with shaker for both weighted / unweighted mud in various drilling.

Applications of Desanders and Desilters

Desilter is used for secondary solid control treatment of mud and liquid to be treated in land and offshore oil and gas drilling/coal bed methane excavation/non-excavation directional crossing/piling engineering/waste sewage, mud treatment and other projects. In short, it is suitable for the desilting treatment of mud and solid-liquid mixture in various environments. The particle size generally excluded is 14-44 microns.

Desander is used for secondary solid control treatment of mud and liquid to be treated in land and offshore oil and gas drilling/coal bed methane excavation/non-excavation directional crossing/piling engineering/waste sewage, mud treatment and other projects. In short, it is suitable for sand removal treatment of mud and solid-liquid mixture in various environments. A typical exclusion particle size is >47 microns.

Price of Desanders and Desilters

The Desanders and Desilters Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Desanders and Desilters. If you are looking for Desanders and Desilters, please kindly contact us to get the latest Desanders and Desilters price.

Desanders and Desilters Supplier

Sino Mechanical, as a Desanders and Desilters manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Desanders and Desilters. We are global Desanders and Desilters supplier. We offer a wide range of drilling equipment and have Desanders and Desilters for sale. We also provide OEM services. We design, manufacture, and sell Desanders and Desilters for your drilling applications. If you want to know latest Desanders and Desilters price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Desanders and Desilters

Model | J752J-1S/2S | J703J-S2SJ | J703J-S3SJ | S-2SJ/3SJ | |

Capacity | 120/240m³/h | 240m³/h | 360m³/h | 240/360m³/h | |

Desander Size(Inch) | 10″ | ||||

Desander Qty | 1/2 Pc | 2 Pcs | 3 Pcs | 2/3 Pcs | |

Working Pressure | 0.25~0.4Mpa | ||||

Feeding Size | DN150 | ||||

Output Size | DN200 | ||||

Bottom Shaker Specs. | Shaker Model | S752J | S703J | N/A | |

Vibration Mode | Linear Motion | ||||

Vibration Motor | 2×1.0Kw | 2×1.72Kw | |||

Screen Qty | 2 Panels | 3 Panels | |||

Screen Size | 750×900mm | 700×1250mm | |||

Screen Area | 1.35m² | 2.63m² | |||

Adjust G Force | ≤7.1G(Adjustable) | ≤7.5G(Adjustable) | |||

Vibration Amplitude | 3.92~5.62mm | 4.14~5.96mm | |||

Deck Angle Range | +2° | -1~+5° | |||

EX Standard | ExdIIBt4/IECEX/A-TEX | ||||

Weight(Kg) | 1059/1114kg | 1835kg | 1924kg | 502/559kg | |

Dimension:mm | 1676×1754×1822 | 2419×2131×1656 | 2419×2135×2066 | 2177×1000×1901 | |

The above specification and parameters for reference only. | |||||