Description

Overview of Reciprocating Pumps

Reciprocating pumps are mechanical devices that converts hydraulic energy from mechanical energy into a fluid. The outstanding advantage of the reciprocating pump is that it can obtain high discharge pressure, and the flow rate has nothing to do with the pressure.

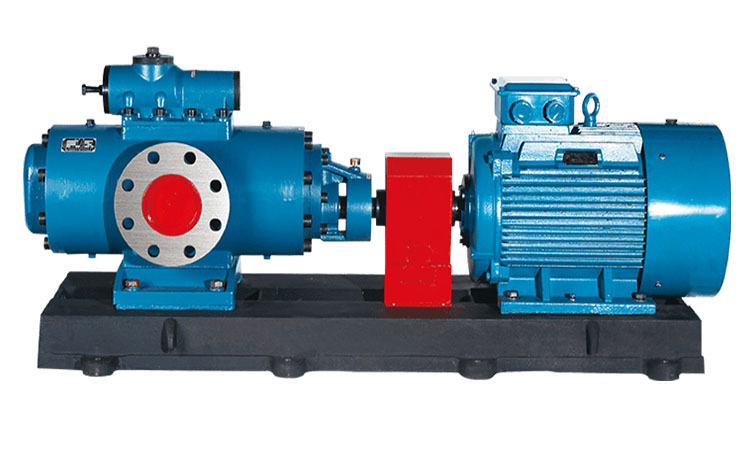

The reciprocating pump is the earliest power machinery developed and belongs to a type of positive displacement pump. The reciprocating pump relies on the reciprocating motion of the piston (or plunger) to periodically change the volume of the working chamber of the pump cylinder. The reciprocating pump converts the mechanical energy of the prime mover into the pressure energy of the liquid. Reciprocating pumps are also called positive displacement pumps or piston pumps because of the use of a piston or plunger during pumping.

The performance of the pump does not change with the pressure and the viscosity of the conveying medium. Reciprocating pumps are often used to transport liquids with high viscosity, high density, high sand content and high corrosiveness under high pressure, and the flow rate is relatively small.

The reciprocating pumps produced by Sino Mechanical Equipment include metering pumps, diaphragm pumps, plunger pumps, and piston pumps. Sino Mechanical reciprocating pumps are suitable for petroleum, product oil, thermal oil, acid, alkali, salt, liquid ammonia, methylammonium (ammonium carbamate), mud, heavy water, clean water, demulsifier, scale inhibitor, corrosion inhibitor, ethylene glycol and other chemical additives.

Features of Reciprocating Pumps

1. Adopt high-performance plunger and special packing, sealing components, long service life and superior sealing performance.

2. The inlet and outlet adopt high-precision one-way valve group to effectively ensure the measurement accuracy and circulation.

3. Simple structure, easy maintenance and high cost performance.

4. The stroke can be adjusted steplessly from 0-100%. Measurement accuracy ± 0.5%.

5. Oil-immersed lubrication ensures long-term reliable use of the transmission mechanism.

6. There are various flow adjustment methods, such as manual, electric, pneumatic, and frequency conversion.

7. Equipped with an electric stroke adjustment mechanism, which can realize remote automatic control.

8. Double or multi-heads can be connected in parallel. The same medium can be delivered by multiple pump heads to reduce pulse. It can also transport a variety of media and be used as a proportional pump.

9. The flow has nothing to do with the lift

The flow rate of the reciprocating pump is only related to the diameter D of the piston, the stroke S and the number of reciprocations n, but has nothing to do with the head of the pump. The flow rate of the reciprocating pump is basically constant under any pressure in the discharge pipeline. The relationship curve between flow rate and head is basically a straight line. However, at high pressure, the flow rate decreases slightly due to increased leakage losses. Therefore, the reciprocating pump cannot adjust the flow rate by adjusting the discharge valve to change the discharge pressure like a centrifugal pump. In addition, because the flow rate of the reciprocating pump has nothing to do with the discharge pressure, the reciprocating pump is suitable for transporting liquids with relatively high viscosity.

10. With self-priming ability

The reciprocating pump does not need to prime the pump before starting like the centrifugal pump, and the reciprocating pump can suck liquid by itself. However, it is still desired that the pump be filled with liquid during actual use. On the one hand, it can realize the immediate suction and discharge of the liquid, and on the other hand, it can also avoid the dry friction of the piston (or plunger) in the pump cylinder. The self-priming capacity of the reciprocating pump is related to the speed. The increase of speed not only increases the resistance of liquid flow, but also increases the inertia loss in liquid flow. When the pressure in the pump cylinder is lower than the vaporization pressure of the liquid, it will cause the pump to evacuate and lose its suction ability. Therefore, the speed of the reciprocating pump should not be too high. Generally, the speed of the reciprocating pump is 80~200r/min, and the suction height is 4~6m. Reciprocating pumps can transport liquid and gas mixtures, and specially designed ones can also transport mud, concrete, etc.

11. High efficiency and wide efficient area. It can reach very high pressure, and the pressure change hardly affects the flow. Therefore, a constant flow rate can be provided. The resulting head can be infinitely high.

The head of the reciprocating pump depends on the characteristics of the device in which the pump works. The smaller the opening of the discharge valve, the more difficult it is to discharge the liquid in the pump cylinder. But the time required for the piston to reciprocate a stroke is approximately constant. The liquid is approximately incompressible, so the pressure of the output liquid (that is, the generated head) is also higher. As long as the prime mover has sufficient power, the material strength of the pump and pipeline is sufficient, and the packing seal has corresponding sealing performance, theoretically speaking, the discharge pressure of the reciprocating pump can be infinitely high. That is to say, the same reciprocating pump can produce different heads in different devices.

It can be seen from this that reciprocating pumps cannot perform "closed start" like centrifugal pumps. At the same time, from a safety point of view, a safety valve must be installed in the reciprocating pump device. The safety valve can prevent the occurrence of vicious accidents such as "suffocating the pump" caused by the blockage of the discharge valve.

12. Can be used as a metering pump

The flow rate of the positive displacement pump depends on the size and frequency of the volume change of the sealed working chamber. When the reciprocating pump is working normally, the flow rate of the pump can be calculated according to the volume of the liquid cylinder and the number of times of reciprocation. By employing various stroke adjustment mechanisms, reciprocating pumps can be used as metering pumps.

13. The flow is uneven, and the flow and pressure have large pulsations.

The process of suction and discharge of liquid by the reciprocating pump is discontinuous. And the piston of the reciprocating pump does linear motion with variable speed. Therefore, the instantaneous flow rate of the reciprocating pump is uneven, and the discharge pressure fluctuates. The pump is prone to shock and vibration during operation. Especially for single-acting pumps, the pulsation is greater due to the acceleration of the piston movement and the intermittent nature of the liquid discharge. It is usually necessary to have an air chamber on the discharge line (and sometimes also on the suction line) to make the flow more even. The use of double-acting pumps and multi-cylinder pumps can also significantly improve the unevenness of flow. Especially when the change frequency of the discharge pressure is equal to or an integer multiple of the natural frequency of the discharge pipeline, resonance will be caused. The flow and pressure pulsation of the reciprocating pump will cause uneven load on the prime mover and shorten the service life of the pump and pipeline. At the same time, the pulsation of flow and pressure will also make the suction condition of the reciprocating pump worse. Therefore, the structure of reciprocating pumps often adopts multi-cylinder pumps, double-acting pumps and air chambers to reduce the pulsation of flow and pressure.

14. Low speed. The size is large. The structure is more complicated than the centrifugal pump. A dedicated pump valve is required. Manufacturing costs and installation costs are high. The piston pump is mainly used for water supply, and the manual piston pump is a widely used domestic water pump. Piston pumps are used to provide high-pressure liquid sources, such as high-pressure water supply for hydraulic presses. Both plunger pumps and piston pumps can be used as drilling mud pumps and oil well pumps in oil fields. Diaphragm pumps are especially suitable for conveying highly toxic, radioactive, corrosive liquids, precious liquids and liquids containing abrasive solids. Diaphragm pumps and plunger pumps can also be used as metering pumps.

At present, the maximum pressure of the reciprocating pump can reach more than 1000MPa. Compared with centrifugal pumps, reciprocating pumps generally have higher efficiency, especially at low flow rates. The main disadvantages of reciprocating pumps are bulky, heavy, complex structure, high cost, and uneven flow.

Applications of Reciprocating Pumps

1. Reciprocating pumps are suitable for conveying various media with small flow rate and high lift, especially special media. Reciprocating pumps are used for high viscosity, highly corrosive, flammable, explosive and toxic media. When the flow rate is less than 100m3/h and the discharge pressure is greater than 9.81MPa, it can show that the reciprocating pump has relatively high efficiency and good operating characteristics.

2. In the petrochemical industry, in the production of synthetic rubber, synthetic plastics, synthetic fibers, and synthetic ammonia, reciprocating pumps are mainly used to pressurize and transport liquid raw materials, catalysts, and various process media. Urea production requires reciprocating high-pressure methylamine pumps and liquid ammonia pumps, whose discharge pressure reaches 21. 6~34. 3MPa, and synthetic ammonia production requires electric reciprocating pumps for transporting copper liquid.

3. In the petroleum industry, drilling mud pumps and oil well fracturing pumps are important equipment in drilling and oil production engineering. High-pressure water injection pumps and polymer injection pumps are key equipment in the secondary oil recovery process and tertiary oil recovery process adopted by oil fields to increase crude oil production. With the development of the petroleum industry, a large number of offshore and deep-sea oil fields have been developed. Pipeline transportation increases, and reciprocating pumps gradually develop in the direction of high pressure and high power.

4. The reciprocating impurity pump plays a key role in the process of transporting suspended solids with high power, large flow, long distance, and its power reaches 2200kW. Reciprocating pumps are used to transport coal slurry and metal slurry in coal mining and mining industries, concrete in construction industry, and mortar in thermal power stations, and are widely used in many occasions.

5. As the main power equipment of large-scale forging machinery, the reciprocating pump is required to provide a working medium with high pressure, large flow rate and small flow pulsation. The reciprocating pump is also mainly used to transport emulsion, clean water and hydraulic oil.

6. The reciprocating pump is also used as a power source for high-pressure cleaning and hydraulic cutting. Most of these products are three-cylinder or single-cylinder plunger reciprocating pumps. Generally it works intermittently. Therefore, the pump speed is high, the pump is small in size and light in weight, and its working pressure can reach 150MPa.

7. Plunger type reciprocating pump is also widely used in chemical process. In addition to conveying liquid, this pump also has the function of continuous measurement and the function of controller. Therefore, many departments use the metering pump as a precision industrial instrument, and the metering pump is especially suitable for mixing one or more media in a certain proportion. Metering pumps are divided into plunger metering pumps, mechanical diaphragm metering pumps and hydraulic diaphragm metering pumps according to the structure of hydraulic pressure components.

8. Discharging mud from underground drilling can also suck up river silt

9. Drainage facilities such as underground garages in high-rise buildings

10. Wastewater discharge in petrochemical and other industries

11. It can also be used for agricultural irrigation, etc.

Price of Reciprocating Pumps

The Reciprocating Pumps Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Reciprocating Pumps. If you are looking for Reciprocating Pumps, please kindly contact us to get the latest Reciprocating Pumps price.

Reciprocating Pumps Supplier

Sino Mechanical, as a Reciprocating Pumps manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Reciprocating Pumps. We are global Reciprocating Pumps supplier. We offer a wide range of drilling equipment and have Reciprocating Pumps for sale. We also provide OEM services. We design, manufacture, and sell Reciprocating Pumps for your drilling applications. If you want to know latest Reciprocating Pumps price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Flow rate: Q=0.5~200000L/H

Pressure difference: ΔP≤104MPa

Payment Terms: TT

We can design and produce reciprocating pump as per your technical requirements.

Types of Sino Mechanical Reciprocating Pumps

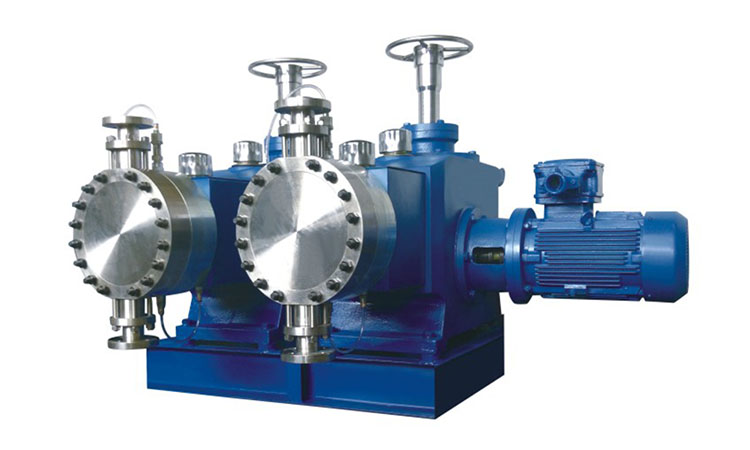

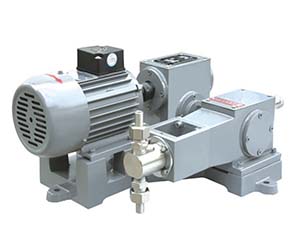

1. Reciprocating Diaphragm Metering Pump (Controlled Volume Pumps)

SINOWA, SINO2WA, SINOWAA, SINO2WAA, SINO3WAA, SINOXAA, SINO2XAA, SINO3XAA, SINODA, SINO2DA, SINO3DA, series metering pump

The plunger of Controlled Volume Pumps contact with the medium directly. And the volume of the working chamber is periodically changed through the reciprocating movement of the plunger. And it will achieve the purpose of suction and discharge of the medium.

○ The stroke is controlled by the screw positioning of the micrometer principle and can be locked.

○ The accuracy of the metering pump is ±1%, which can be adjusted manually or by frequency conversion.

○ The pump head can be divided into hydraulic diaphragm type, plunger type and piston type.

○ It is extremely easy to operate and maintain.

○ 2J-W and 3J-W series can be used as proportional pumps. After the pump heads are connected in parallel, the flow rate can be increased and the pulse can be smoothed

○ The liquid end is divided into plunger type and hydraulic diaphragm type.

○ Motor adopts vertical installation, safe and leak-free.

○ The accuracy of the metering pump is ±1%, which can be adjusted by manual, frequency conversion and electric travel actuators

○ It can be connected in parallel into 2 cylinders, 3 cylinders or multiple cylinders to increase the flow and smooth the pulsation

○ Material of medium flow part: 304 or 316 stainless steel, PVDF, PVC, PP and other suitable polymer materials

○ Hydraulic diaphragm pump adopts built-in safety valve and replenishing valve, which can automatically exhaust and replenish oil, with superior and reliable performance

○ The hydraulic end of the plunger pump adopts the new technology, and the plunger seal has no leakage

○ High measurement accuracy, the flow can be adjusted steplessly by manual and frequency conversion

○ High-performance plunger and special packing, diaphragm, seal assembly, long service life and superior sealing performance.

○ The material of the medium flow part can be 304 or 316 stainless steel, PVDF, PVC, PP, etc.

○ Equipped with a high-precision check valve, the plunger seal adopts the invention patent technology, and there is no leakage in long-term operation

○ Internal circulation pressure balance system and special protection structure, the diaphragm has a longer service life

○ The actual service life of hydraulic diaphragm pump plunger and plunger seal has exceeded 30,000 hours

○ Adjustable range: 10 ~ 100%, measurement accuracy: ± 0.5%.

○ The actual service life of the diaphragm has exceeded 20,000 hours

○ Diaphragm damage alarm system can be configured.

○ Various flow adjustment methods, including manual, electric, pneumatic, frequency conversion adjustment.

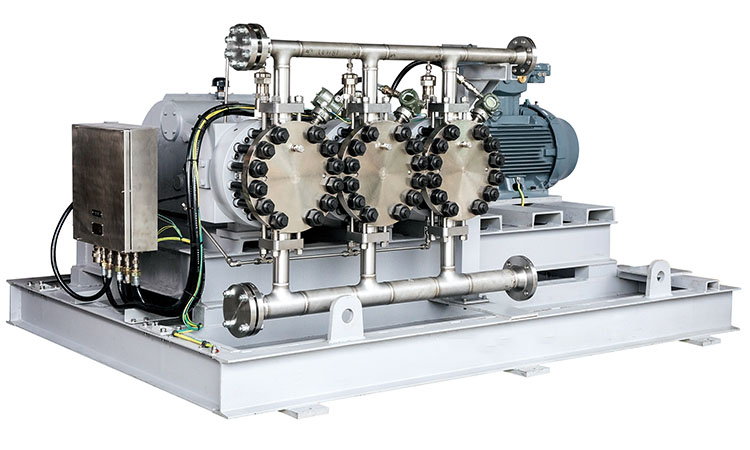

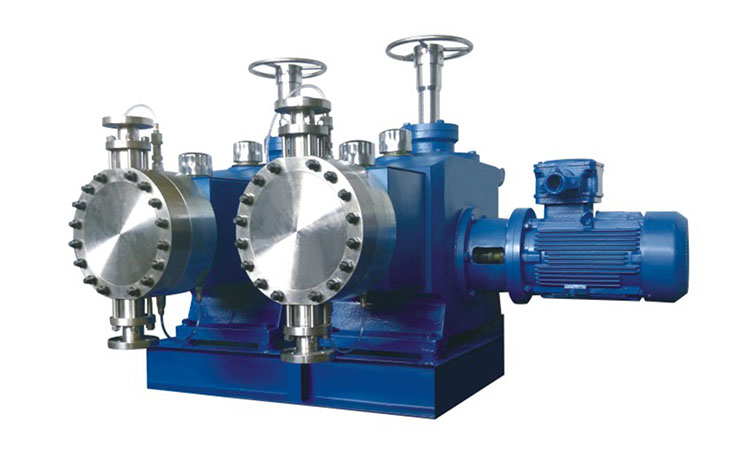

2. Reciprocating Plunger Metering Pump(Controlled Volume Pumps)

SINOWA, SINOXAA, SINOZA, SINO2ZA, SINO DA series metering pump

○ High-performance plunger and special packing and sealing components. long service life and superior sealing performance.

○ Advance and export adopt high-precision check valve group to ensure metering accuracy and circulation.

○ Simple structure, convenient maintenance and high cost performance.

○ Integrated "Oude" worm gear auxiliary transmission mechanism, low noise and high efficiency.

○ Using a integral sleeve adjustable eccentric transmission mechanism. It is simple and reliable. The stroke can be 0-100% stepless adjustment. And the measurement accuracy is ±0.5%.

○ Oil-immersed lubrication to ensure long-term reliable use of the transmission mechanism.

○ Various flow adjustment methods, such as manual, electric, pneumatic and frequency conversion.

○ With electric stroke adjustment mechanism, it can realize remote automatic control.

○ It can be double or multi-headed in parallel, up to 12 heads. Multiple pumps can be used to deliver the same medium to reduce the pulse. Or a variety of media can be transported for use as a proportional pump.

○ Without safety relief device, it is recommended to install a safety valve on the outlet line of the pump.

○ The pump head can be 304, 316, 316L, 904, Hastelloy C, polymer, etc.

○ Widely used in petrochemical, natural gas, oil and gas fields, plastic foam, electricity, metallurgical cleaning and other fields. Especially in the process of conveying various liquid media such as high viscosity, high pressure and high temperature, it is particularly popular.

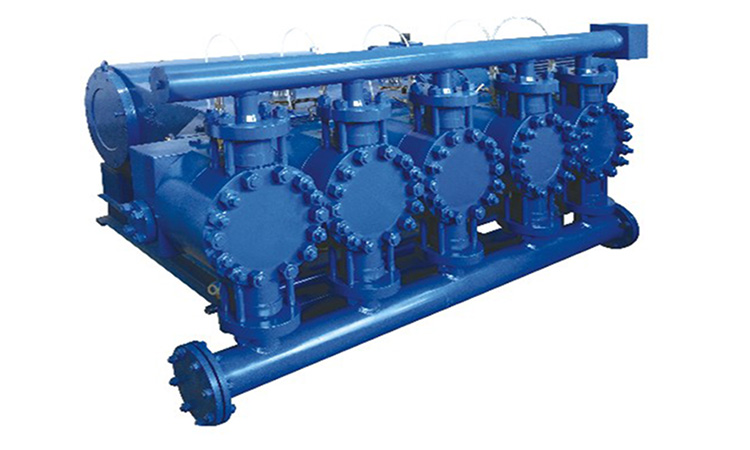

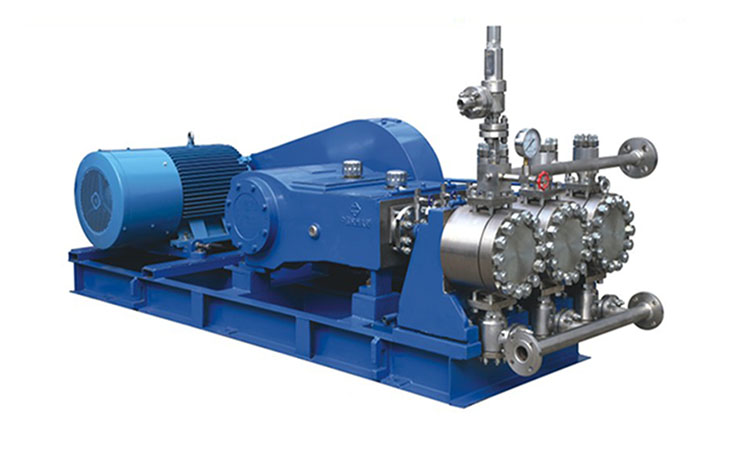

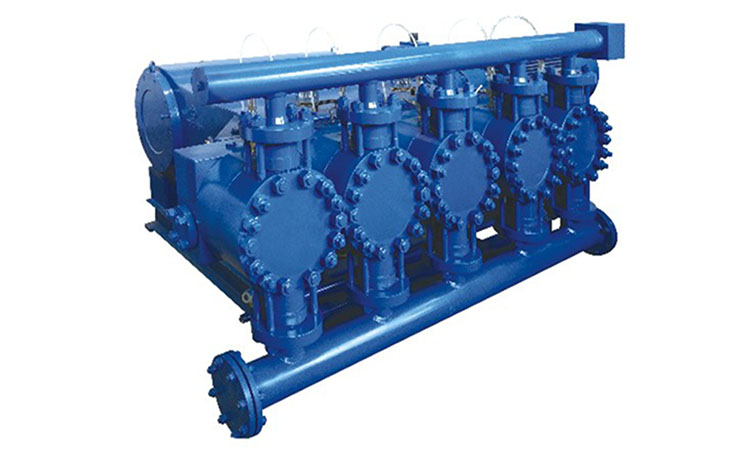

3. High-pressure Reciprocating Pump (Plunger/Diaphragm)

SINO3CM, SINO3EM, SINO3HM, SINO3KM, SINO3MM, SINO3NM, SINO5JM, SINO5PM

○ Performance parameters: Flow range: 4.65 ~ 96.89m³ / h.

○ Pressure range: 5.3 ~ 104MPa.

○ Main application: Suitable for water injection, polymer injection, alcohol injection, chemical engineering, fertilizer process pumps, carbon dioxide pumps, cleaning, phosphorus removal, rust removal pumps, etc. in oil and gas fields, zero leakage of media, especially suitable for the transportation of toxic, corrosive and volatile workers condition.

○ Small pulsation and smooth transportation.

○ Installation form: horizontal, vertical, fixed, mobile.

○ Transmission mode: internal double helical gear, external reducer, pulley, frequency conversion speed regulation.