Description

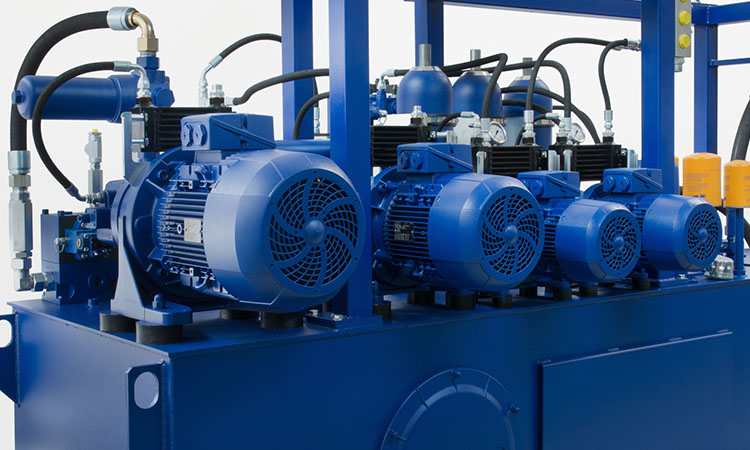

Overview of Hydraulic Power Units

Hydraulic Power Units are the main driving components of hydraulic systems. Hydraulic pump station, also known as hydraulic power unit and hydraulic pump system, is an independent hydraulic device. The hydraulic pump station supplies oil according to the requirements of the driving device (host), and controls the direction, pressure and flow of oil flow.

HPU is the power source for generating the flow of hydraulic fluid for the desired application. They being said, the combinations are endless and at advanced fluid power, we design and build custom power units to the specification of the customer. Mainly consist of motor, pump, coupling, adjustable pressure control, pressure gauge, reservoir, etc.

The hydraulic pump station is suitable for various hydraulic machines where the main engine and the hydraulic device can be separated. The motor drives the oil pump to rotate. The hydraulic pump station is an electromechanical device that provides lubrication and power for the mechanical operation of large and medium-sized industries. The hydraulic system is used because the hydraulic system has the characteristics of wide application, high efficiency and simple structure in power transmission. The primary task of a hydraulic system is to transfer power from one form to another.

The Hydraulic Power Units is also called the hydraulic pump station. The motor drives the oil pump to rotate. The pump pumps oil after absorbing oil from the oil tank, and converts the mechanical energy into the pressure energy of the hydraulic oil. After the flow is adjusted, it is transmitted to the oil cylinder or oil motor of the hydraulic machine through the external pipeline, thereby controlling the change of the direction of the hydraulic machine, the magnitude of the force and the speed of the speed, and pushing various hydraulic machines to do work.

The hydraulic power unit is a hydraulic source device composed of a hydraulic pump, a driving motor, a fuel tank, a directional valve, a throttle valve, a relief valve, or a hydraulic device including a control valve. Supply oil according to the flow direction, pressure and flow required by the driving device. It is suitable for all kinds of machinery where the driving device and the Hydraulic Power Units are separated. Connect the Hydraulic Power Units and the driving device (oil cylinder or motor) with oil pipes, and the hydraulic system can realize various regulations. Actions.

The hydraulic system consists of five parts, including power components, actuators, control components, auxiliary components (accessories) and hydraulic oil. The main function of the hydraulic system is power transmission and motion control, and it fulfills various requirements of hydraulic equipment. The Hydraulic Power Units is composed of a pump device, a manifold or a valve combination, a fuel tank, an electric control, and an accumulator. The Hydraulic Power Units is the power system for changing and cleaning the filter screen of the screen changer.

Features of Hydraulic Power Units

1. Classic high and low pressure hydraulic control system, energy saving and environmental protection green design.

2. Strict process design ensures high energy utilization rate.

3. Low noise, no leakage.

4. The main components are international famous brands, and the safe and stable system will meet.

5. Compact structure, strong power, high working frequency

6. All components ensure good interchangeability, which can ensure the stable operation of the hydraulic pump station

7. The engine and oil pump are equipped with an oil machine alarm system to protect the engine and oil pump

8. The hydraulic oil pollution indicator can remind you to replace the hydraulic oil and filter element in time. The pressure gauge can keep an eye on the working status of the oil pump

9. The hydraulic oil air-cooled radiator can better ensure the machine to work for a long time and prolong the life of the oil pump and other working components

10. Equipped with double oil filters, which can better ensure the cleanliness of hydraulic oil

11. The surface is sprayed with plastic, beautiful and beautiful, anti-rust and corrosion-resistant.

12. It can automatically realize overload protection to prevent mechanical damage.

13. Light weight, small size, small motion inertia, fast response.

14. It is easy to operate and control, and can realize stepless speed regulation in a wide range.

15. It is easy to realize the automation of the machine. Using electro-hydraulic joint control, not only can realize a higher degree of automatic control process, but also can realize remote control.

16. Can be used in onshore and offshore drilling operation, desert and continuous working situation.

17. Wide adjustment range, easy operation, high generality.

18. Air or water cooled.

19. Electric driver and diesel drive.

Types of Hydraulic Power Unit

The structural form of the Hydraulic Power Units is mainly distinguished by the structural form, installation location and cooling method of the pump device.

According to the mechanism form and installation position of the pump device, it can be divided into:

1. Top-mounted vertical: The pump device is installed vertically on the fuel tank cover, mainly used in quantitative pump systems.

2. Top-mounted horizontal type: The pump device is installed horizontally on the oil tank cover, and is mainly used in variable pump systems to facilitate flow adjustment.

3. Side-mounted type: The pump device is installed horizontally on a separate foundation next to the fuel tank. The side-mounted type can be equipped with a spare pump. It is mainly used for systems with a large fuel tank capacity of 250 liters and a motor power of 7.5 kW or more.

According to the cooling method can be divided into:

1. Natural cooling: it is cooled by heat exchange between the fuel tank itself and the air, and is generally used in systems with a fuel tank capacity of less than 250 liters.

2. Forced cooling: A cooler is used for forced cooling, which is generally used in systems with a fuel tank capacity greater than 250 liters. The main technical parameters of the Hydraulic Power Units are the effective oil storage measurement of the fuel tank and the power of the motor. There are 18 types of fuel tank capacity (unit: liter/L): 25, 40, 63, 100, 160, 250, 400, 630, 800, 1000, 1250, 1600, 2000, 2500, 3200, 4000, 5000, 6000 books According to user requirements and operating conditions, the series of Hydraulic Power Unitss can do: ① Configure integrated blocks according to the system, or without integrated blocks; ② Coolers, heaters, and accumulators can be set; ③ Electrical control devices can be set, Also available without electrical control

According to the form of fuel tank, it can be divided into:

1. Ordinary steel plate: the box body is welded with 5MM-6MM steel plate, and the panel is made of 10-12MM steel plate. If there are too many holes, it can be thickened or added with reinforcing ribs.

2. Stainless steel plate: 304 stainless steel plate is used for the box body, the thickness is 2-3MM, the panel is made of 304 stainless steel plate, the thickness is 3-5MM, and the load-bearing parts are added with reinforcing ribs.

3. It is difficult to implement anti-rust treatment inside the ordinary steel plate oil tank. Rust entering the oil circulation system will cause many failures. The oil tank designed with all stainless steel solves this industry problem.

According to the structure form can be divided into:

1. Piston type

Single rod hydraulic cylinders have a piston rod at only one end. As shown in Figure 3 is a single-piston hydraulic cylinder. The inlet and outlet oil ports A and B at both ends can pass through pressure oil or return oil to realize two-way movement, so it is called double-acting cylinder.

2. Plunger type

①The plunger hydraulic cylinder is a single-acting hydraulic cylinder, which can only move in one direction by hydraulic pressure, and the return stroke of the plunger depends on other external forces or the self-weight of the plunger;

②The plunger is only supported by the cylinder liner without contact with the cylinder liner, so the cylinder liner is very easy to process, so it is suitable for long-stroke hydraulic cylinders;

③The plunger is always under pressure when working, so it must have sufficient rigidity;

④ The weight of the plunger is often large, and it is easy to sag due to its own weight when it is placed horizontally, causing unilateral wear of the seal and guide, so it is more beneficial to use it vertically.

3. Telescopic

Telescopic hydraulic cylinders have two-stage or multi-stage pistons. The order of piston extension in telescopic hydraulic cylinders is from large to small, while the order of no-load retraction is generally from small to large. The telescoping cylinder can achieve a long stroke, and the length is short when retracted, and the structure is more compact. This type of hydraulic cylinder is often used in construction machinery and agricultural machinery.

4. Swing type

The swing hydraulic cylinder is an actuator that outputs torque and realizes reciprocating motion, also known as a swing hydraulic motor. There are two forms of single blade and double blade. The stator block is fixed to the cylinder, while the vanes and rotor are connected together. According to the oil inlet direction, the blade will drive the rotor to swing back and forth.

Applications of Hydraulic Power Units

Hydraulic Power Units can generally be used in any application that requires heavy and systematic lifting or other requirements for the repeated use of powerful and directional force.

The main function of the Hydraulic Power Units is to convert mechanical energy into hydraulic energy, and provide many functions such as pressure, flow and direction control according to system requirements. Widely used in industry, engineering machinery, marine ships, metallurgy, aviation and other fields. It is one of the important equipment to ensure the safe operation of a mechanical device system. The function of the press station is to transmit force. Huge pressure is generated through the hydraulic pump, and different movements are realized through many transmission parts such as oil cylinders and pistons, including upward power and horizontal movement power. Hydraulic Power Units are widely used in automotive braking, industry, engineering decks, marine ships, metallurgy, aviation and other fields.

1. Machine Tools

2. Automation

3. Meat Processing Machinery

4. Mobile Equipment

5. Aerospace Test Equipment

6. Rolling Mill Machinery

7. Material Handling

8. Agricultural Equipment

9. Paper Mill Machinery

10. Government/Military

11. Oil Field

12. Oil Spill Clean Up Equipment

13. Industrial Process

14. Marine Equipment

15. Construction Equipment

16. Theatrical & Production Equipment

Hydraulic Power Units consist of:

1. Functional parts:

The Hydraulic Power Units is composed of a pump device, a manifold or a valve combination, a fuel tank, and an electrical box. The functions of each component are as follows:

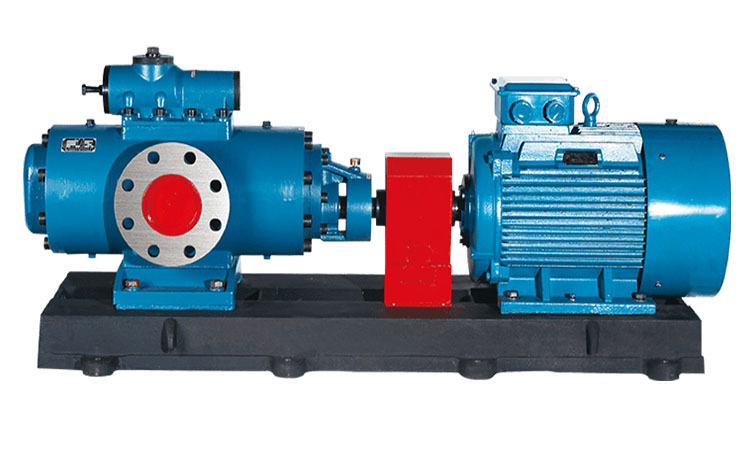

Pump device - equipped with a motor and an oil pump, which is the power source of the Hydraulic Power Units and converts mechanical energy into power energy of hydraulic oil.

Manifold - is composed of a hydraulic valve and a channel body. It regulates the direction, pressure and flow of hydraulic oil.

Valve combination - the plate valve is installed on the vertical plate, and the pipe is connected behind the plate, which has the same function as the manifold.

Oil tank——It is a semi-closed container welded by steel plate, and it is also equipped with oil filter screen, air filter, etc. It is used for oil storage, oil cooling and filtration.

Electrical box - divided into two forms: one is equipped with terminal boards for external leads; the other is equipped with a full set of control electrical appliances.

2. Components

⑴Electric motor, gear pump—provide driving force for the hydraulic system.

⑵Solenoid reversing valve—control the direction of hydraulic oil flow and change the direction of movement of the cylinder.

⑶ Electromagnetic overflow valve - to prevent overpressure of the entire hydraulic system, equivalent to a safety valve, to protect the safety of the oil pump and oil circuit system and to keep the pressure of the hydraulic system constant.

⑷Decompression valve——By adjusting the pressure relief valve, different working mechanisms can meet the requirements of different working pressures, so that the pressure of the secondary oil circuit is lower than that of the primary oil circuit.

⑸Speed control valve—Throttling and speed regulation of the oil circuit can change the working speed of the hydraulic cylinder of the actuator.

⑹Hydraulic oil filter—there are two oil filter ports in the Hydraulic Power Units. One is installed at the oil suction port of the gear pump to avoid inhaling impurities such as particles in the hydraulic oil of the oil tank. The other is installed on the hydraulic oil delivery pipeline of the system to remove impurities in the hydraulic oil, and at the same time remove colloids, asphaltenes, and carbonized particles produced by the chemical changes of the hydraulic oil itself. In this way, failures such as spool sticking and damping hole blockage can be prevented. The pipeline system is equipped with a differential pressure alarm device. When the filter element is clogged, an electric signal is sent out. At this time, the filter element should be cleaned or replaced.

⑺Pressure gauge - used to display the working pressure of the Hydraulic Power Units, so as to facilitate the operator to control the oil pressure.

⑻Air filter—installed on the fuel tank, it has three functions, one is to prevent pollutants in the air from entering the fuel tank; the other is to change the air to prevent the oil pump from being sucked; the third is to serve as a hydraulic oil replenishment port.

⑼Oil level gauge—installed on the side of the oil tank to display the liquid level of hydraulic oil.

⑽Temperature gauge——Some oil tanks are equipped with a thermometer to display the temperature of the hydraulic oil.

⑾Connecting pipelines—transmitting hydraulic driving force, most of them use steel pipes, and there are also pressure-resistant rubber hoses.

The main parameters of Hydraulic Power Units

Rated Pressure: Under normal working conditions, the hydraulic pump operates continuously and normally, which can guarantee the highest pressure allowed under normal working conditions. The rated pressure is obtained according to the consideration of the structure, material and various comprehensive factors of the equipment. During the working process of the hydraulic pump station, it must be less than this pressure

Maximum Allowable Pressure: that is, the maximum pressure that the hydraulic pump can output

Working Pressure: It is the pressure output by the hydraulic pump station in actual work, also called the outlet pressure of the hydraulic pump. This pressure is determined by the load of the hydraulic pump station. The working pressure rises and falls with the load.

Suction Pressure: Contrary to the output pressure, the pressure at the inlet of the hydraulic pump becomes the suction pressure, and the pressure value of the self-priming pump is lower than the atmospheric pressure. The suction pressure should not be too low, if it is too low, it will cause insufficient oil absorption and cause cavitation.

Price of Hydraulic Power Units

The Hydraulic Power Units Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Hydraulic Power Units. If you are looking for Hydraulic Power Units or Hydraulic Power Units spares, please kindly contact us to get the latest Hydraulic Power Units price.

Hydraulic Power Units Supplier

Sino Mechanical, as a Hydraulic Power Units manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Hydraulic Power Units. We are global Hydraulic Power Units supplier. We offer a wide range of drilling equipment and have Hydraulic Power Units for sale. We also provide OEM services. We design, manufacture, and sell Hydraulic Power Units for your applications. If you want to know latest Hydraulic Power Units price , don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Hydraulic Power Units

MODEL | 120LD-2-5III | 120LD-2-7 | F/S-120LD/-2-2II | F/S120LD-2-2II | F-225D/2VF | S-160LD/2VF | |

RATED FLOW | L/min | 120 | 255(max) | 160/110(max) | |||

gpm | 31.7 | 37.3(max) | 42.3/29.1(max) | ||||

RATED PRESSURE | MPa | 16.6 | / | / | |||

Psi | 2400 | / | / | ||||

MAX. PRESSURE | MPa | 20 | 12/20 | ||||

Psi | 2900 | 1740/2900 | |||||

DRIVE POWER | Kw | 37X2 | 30X2 | 45/51.8 | 45X2 | ||

hp | 49.6X2 | 40X2 | 60.3/69.5 | 60.3X2 | |||

HEATING POWER | Kw | 3X2 | / | 3X2 | |||

hp | 4X2 | / | 4X2 | ||||

COOLING WAY | AIR COOLED | AIR AND WATER COOLED | AIR COOLED | WATER COOLED | |||