The Components and Installation Process of Drilling Mud Pumps

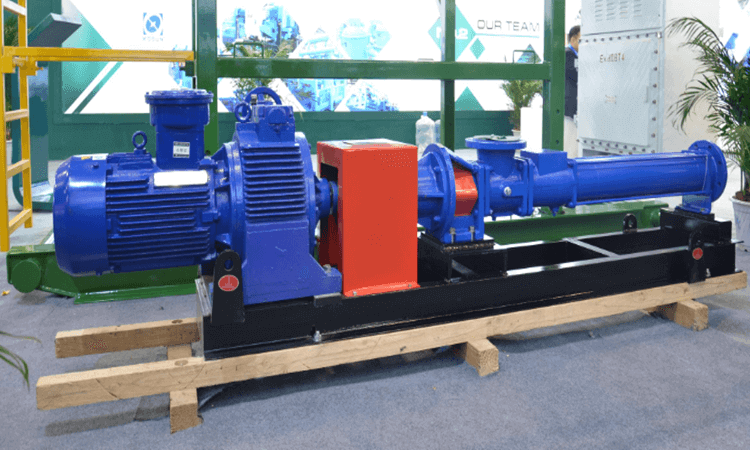

In the realm of petroleum drilling equipment, the mud pump stands as a pivotal component, responsible for transporting drilling mud to cool and lubricate the drill bit, as well as conveying rock cuttings and debris from the wellbore to the surface. To gain a deeper insight into the operation and maintenance of mud pumps, let's delve into their internal components and the installation process.

Internal Components of Mud Pumps

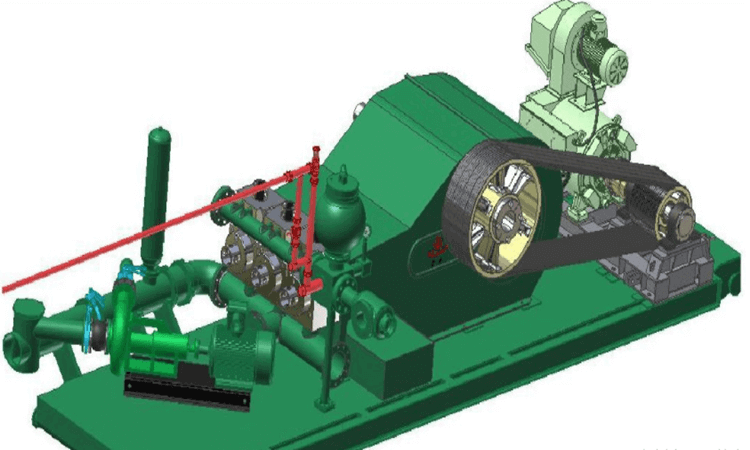

A mud pump's internals can be divided into two main sections: the power end and the fluid end, each comprising several critical components.

Power End

Base and Frame: The base and frame provide structural support for the mud pump, ensuring its stability during operation.

Gear Shaft Assemblies: These include small gear shafts and large gear shaft assemblies, which transmit power to drive the pump head.

Crankshaft Assembly: The crankshaft is a vital component that facilitates the reciprocating motion necessary for suction and discharge of the mud.

Crosshead Assembly: The crosshead is connected to the crankshaft, transmitting power to the fluid end.

DC Motor: A direct current motor supplies power to the mud pump, enabling efficient operation.

Fluid End

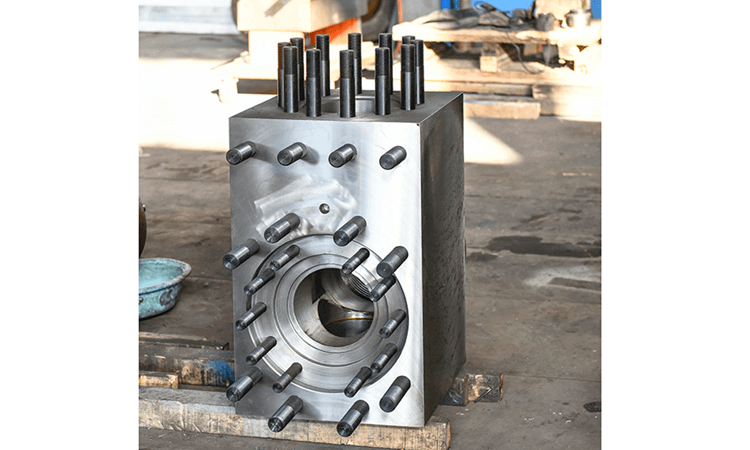

Fluid Cylinder: The fluid cylinder forms part of the pump head and serves as the housing for various other fluid-end components.

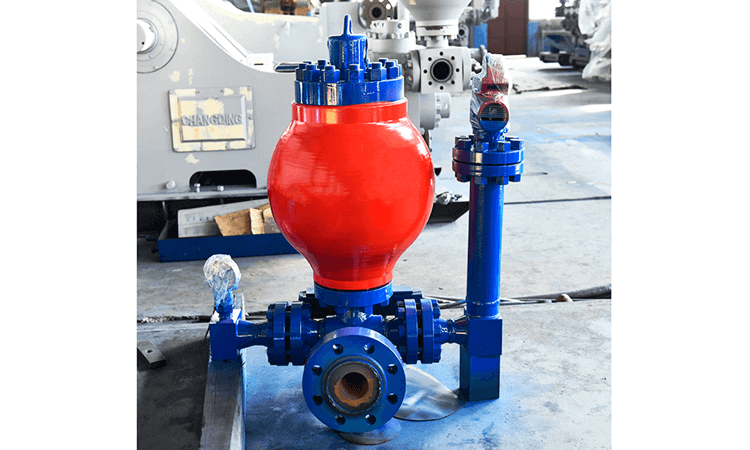

Valves: The fluid end includes suction and discharge valves that regulate the flow of mud.

Liner, Pistons, and Piston Rods: These components work together to draw in and discharge mud from the fluid cylinder.

Suction and Discharge Piping: These pipelines connect the fluid end to the mud tank and other sections, ensuring the flow of mud.

Safety Valve: The safety valve functions to protect the pump body by rapidly relieving pressure when it exceeds the set limit.

Types of Mud Pump Heads

Mud pumps can be categorized into three types based on the arrangement of valves and liners: L-type, I-type, and T-type pump heads.

L-type Pump Head: It has an L-shaped flow passage, resulting in relatively higher flow losses. However, as the suction and discharge valves are separate, it is easier to maintain and replace them.

I-type Pump Head: The flow passage is in the shape of an 'I,' leading to lower flow losses and a lighter pump head. Yet, vertical placement of suction and discharge valves makes maintenance and replacement more challenging.

T-type Pump Head: Featuring a 'T'-shaped flow passage, the T-type pump head combines the advantages of both L-type and I-type designs. However, disassembling the suction valves requires removing the suction cylinder and piping.

Mud Pump Installation Process

Proper installation of a mud pump is critical for its smooth operation and long-term use. The following are key steps in the mud pump installation process:

Base Installation: The mud pump should be installed on a horizontal surface or a slightly inclined base with an inclination of less than 3 degrees to facilitate the flow of lubricating oil and reduce friction between gears.

Location Selection: The choice of installation locations for both the mud pump and mud tank is vital. The mud pump's placement should be as low as possible, while the mud tank should be positioned as high as feasible to enhance suction efficiency and increase mud intake.

Suction Piping Setup: The entrance of the suction pipe should be positioned about 300mm above the bottom of the mud tank. It is crucial to ensure uniform pipe diameters and avoid direct alignment of the suction pipe entrance with the mud tank's inlet.

Safety Valve and Discharge Piping Installation: Install the safety valve and discharge piping according to the manufacturer's instructions, following the recommended sequence.

Secure Piping Lines: Ensure that the suction and discharge piping lines are firmly and securely fastened to prevent unnecessary stress and potential vibrations during operation.

Proper assembly and installation of a mud pump not only extend its operational life but also guarantee its high-performance efficiency during drilling operations. By understanding its internal components and following the correct installation steps, operators can effectively maintain and manage this crucial piece of petroleum drilling equipment.

Sino Mechanical Equipment provides various oil drilling equipment, such as: drilling mud pumps and accessories, diesel engines, air winches, drawworks, traveling block and hook combinations, wire ropes, etc. It is committed to developing and providing high-quality oil drilling equipment to meet the changing needs of customers and contribute more to the development of the petroleum industry.

.png)