Description

Overview of Shale Shaker Screens

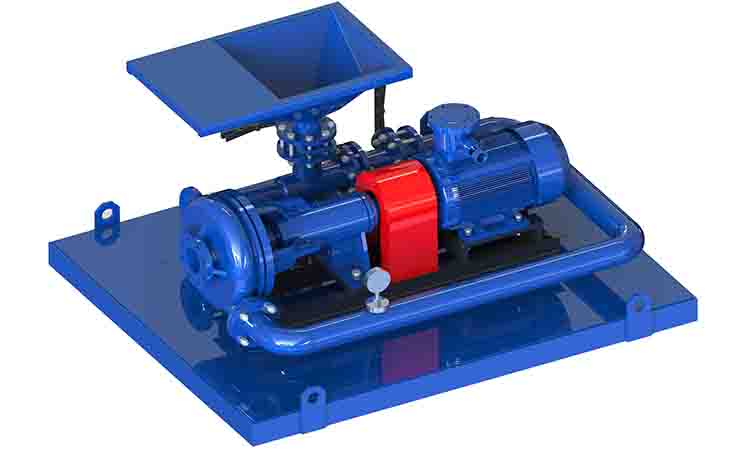

The oil drilling fluid Shale Shaker Screens is a key component in the drilling solid control system. It is mainly used to separate the drilling cuttings and harmful solids in the drilling fluid to ensure the recycling of the drilling fluid.

Shale shaker screens are woven with metal wire or fiber wire, with a pore size of 0.15~1mm. It can remove and recover different types and small suspended solids. The screen separation has the advantages of simplicity, high efficiency and low operating cost. Shale shaker screens are generally used on oilfield drilling solid control vibrating screens to filter drilling mud.

Classification of Shale Shaker Screens

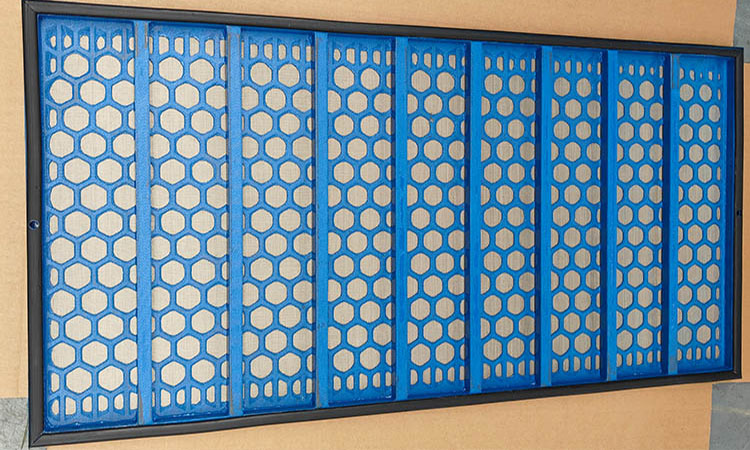

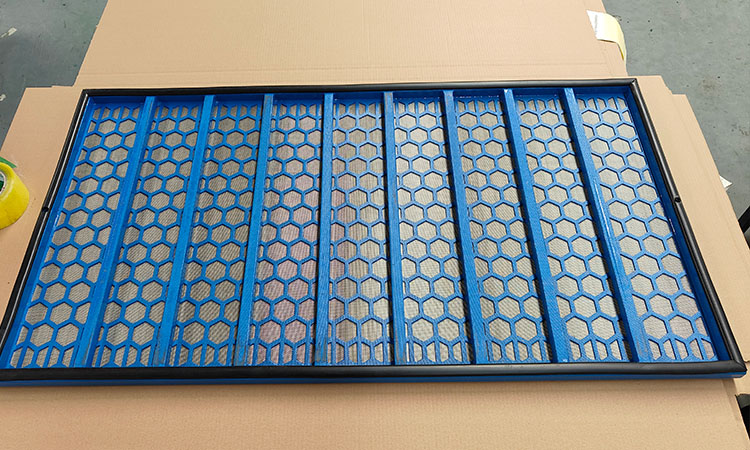

1. Steel Frame Shaker Screen

Steel frame frame screens are a more commonly used type of petroleum shale shaker screens, mainly composed of a steel frame and 2 to 3 layers of stainless steel mesh tightly combined on the frame. The frame is welded from high-strength square steel pipes or flat steels, and has multiple reinforcing support ribs. The mesh can be combined with the frame through metal village glue, or directly bonded to the frame. The high-strength steel frame and support ribs, as well as the moderately tensioned screens, form a reliable whole, greatly enhancing the flow rate, strength and service life that the screens can withstand. The mesh counts of each layer of mesh are different, and accurate and reasonable matching makes the screening effect more delicate. The mesh is divided into multiple independent small mesh surfaces to prevent local damage from over-expansion. At the same time, it is equipped with a special rubber plug to repair the damage, which can save time and reduce the cost of use.

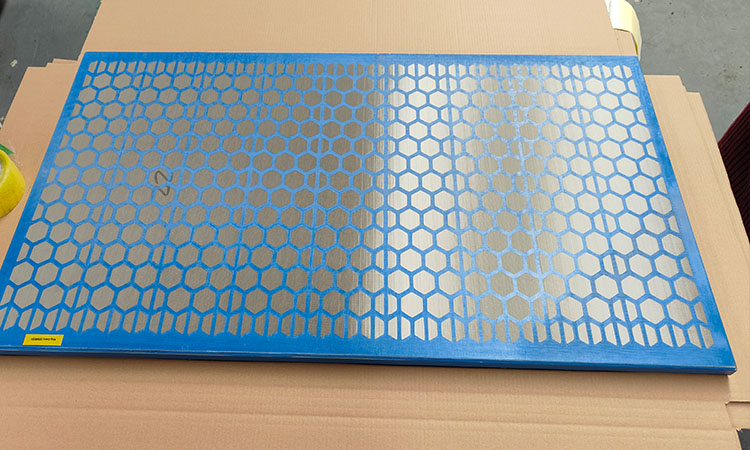

2. Composite Frame Shaker Screen

Composite frames are made of high-strength materials (such as stainless steel, polyurethane or composite materials), combining the rigidity of metal with the corrosion resistance of non-metal. The frame design is usually modular to facilitate installation and replacement. It is an ideal accessory for Shale Shaker Screens, desanders, and desilters.

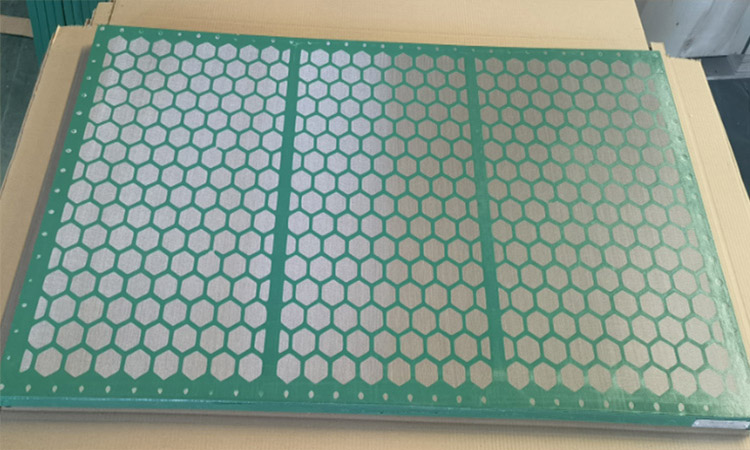

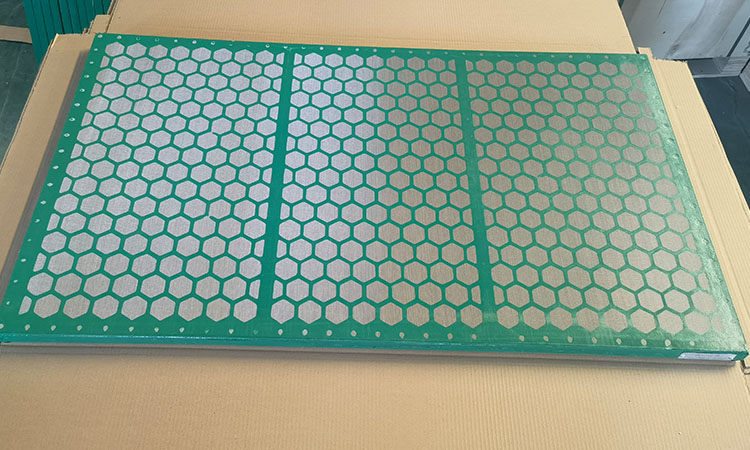

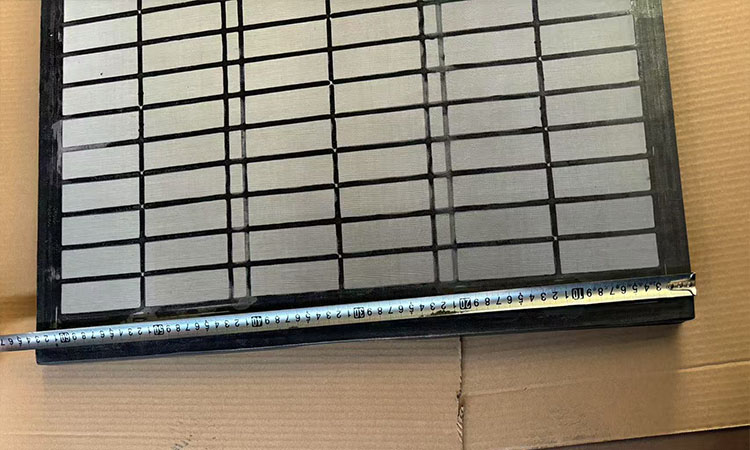

3. Flat Panel Shaker Screen

Flat Panel Shaker Screen is a commonly used oil shaker screen currently, which can be widely used in drilling operations under different conditions. This product is usually composed of 2 to 3 layers of stainless steel mesh cloth bonded to a perforated metal liner. At the same time, the screen is equipped with a special rubber plug to repair the damage of the mesh surface, which can effectively save time and reduce production costs. Our factory has rich production experience and mature technology, and can manufacture hook-edge flat screens of various specifications and sizes according to the needs of different customers.

4. Wave Type Shaker Screen

The wave-type shaker screen is also known as the wave-type mud shaker screen. The screen surface is uniquely wavy. It is made of 2 or 3 layers of stainless steel screen cloth after composite bending and bonding with a metal support plate with openings. The installation method can be a hook edge or a wedge-shaped clamping device of the steel frame mesh. The effective filtration area of the wave screen can reach 125% to 150% of the flat screen of the same specification, and the processing capacity is greatly increased.

Features of Shale Shaker Screens

1. Material properties

High-strength materials: Made of stainless steel (such as 304, 316), low-carbon steel or polyurethane materials, with corrosion resistance and wear resistance.

Fatigue resistance: can withstand high-frequency vibration and cyclic loads, and is not easy to deform or break.

Chemical corrosion resistance: adapt to chemical additives in drilling fluid (such as acids, alkalis, salts) and high temperature environments.

2. Structural design

Multi-layer screen structure: common single-layer, double-layer or three-layer design, different layers can grade and filter solid particles of different particle sizes.

Fine grading: The mesh size range is wide (usually 20-200 mesh), and different precisions can be selected according to drilling needs (such as 40-80 mesh for conventional drilling, 100 mesh or more for fine filtration).

3. Functional characteristics

Efficient separation: The high-frequency vibration of the vibration motor (usually 1000-3600 RPM) quickly separates the solid phase and the liquid phase to improve the recovery rate of drilling fluid.

Anti-blocking design: Some screens adopt an inclined or wavy structure to reduce particle blockage and extend the service life.

Strong adaptability: It can be used with different types of vibrating screens (such as linear screens, elliptical screens, and balanced screens).

4. Performance advantages

Wear resistance: The surface is hardened (such as carburizing, spraying) to extend the service life in abrasive environments.

Easy to replace: Modular design, easy to disassemble and replace quickly, reducing downtime.

Low maintenance: No frequent cleaning is required, and some screens support backwashing or ultrasonic cleaning.

Applications of Shale Shaker Screens

Land drilling: Focus on economy and durability, steel screens are often used.

Offshore drilling: Need to be resistant to salt spray corrosion, 316 stainless steel or polyurethane screens are often used.

High-temperature deep wells: Use high-temperature resistant materials (such as special alloys or high-temperature polyurethane).

Price of Shale Shaker Screens

The Shale Shaker Screens price will change randomly with factors such as production cost, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Shale Shaker Screens. If you are looking for Shale Shaker Screens , please kindly contact us to get the latest price.

Shale Shaker Screens Supplier

Sino Mechanical, as a Shale Shaker Screens manufacturer, has more than 20 years extensive experiences in the drilling equipment. We are global Shale Shaker Screens supplier. If you want to know the latest Shale Shaker Screens price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

| Model | Mesh Size | Screen Size (L x W) | Model for Shaker |

| SMB-01 | API 20 - API 325 | 1053 x 697 mm | FLC 2000 |

| SMB-02 | API 20 - API 325 | 1050 x 697 mm | FLC 500 |

| SMB-03 | API 20 - API 325 | 1070 x 570 mm | HYP |

| SMB-04 | API 20 - API 325 | 710 x 626 mm | DUAL POOL 600 |

| SMC-01 | API 20 - API 325 | 1165 x 585 mm | SWACO MONGOOSE |

| SMC-02 | API 20 - API 325 | 1250 x 635 mm | BRANDT KING COBRA |

| SMC-03 | API 20 - API 325 | 1220 x 720 mm | KEMTRON 48 SERIES |

| SMC-04 | API 20 - API 325 | 913 x 650 mm | BRANDT VSM300 |

| SMD-01 | API 20 - API 325 | 1165 x 585 mm | SWACO MONGOOSE |

| SMD-02 | API 20 - API 325 | 1250 x 635 mm | BRANDT KING COBRA/VENOM |

| SMD-03 | API 20 - API 325 | 913 x 650 mm | BRANDT VSM300 |

| SMD-04 | API 20 - API 325 | 660 x 610 mm | SWACO MD-3 |

| SMD-05 | API 20 - API 325 | Customized | SWACO BEM-600 |

| Model | Mesh Size | Screen Size (L x W) | Model for Shaker |

| BTN-01 | API 20 - API 325 | 1040 x 600 mm | NCS-300 |

| BTN-02 | API 20 - API 325 | 1400 x 460 mm | ZCN |

| BTN-03 | API 20 - API 325 | 1150 x 1000 mm | NS-115/2 |

| BTN-04 | API 20 - API 80 | 927 x 914 mm | JSS(USA) |

| BTN-05 | API 20 - API 80 | 1524 x 1219 mm | SSS(USA) |

| Model | Mesh Size | Screen Size (L x W) |

| SMA-01 | 20-325 | 903×1155mm |

| SMA-02 | 20-325 | 1212×1141mm |

| SMA-03 | 20-325 | 697×1050mm |

| SMA-04 | 20-325 | 697×1053mm |

| SMA-05 | 20-325 | 697×846mm |

| SMA-06 | 20-325 | 915×1150mm |

| SMA-07 | 20-325 | 720×1220mm |

| SMA-08 | 20-250 | 700×1165mm |

| SMA-09 | 20-250 | 1186×1280mm |